Keep Metal

Moving

End-to-End Solutions.

From a Global Innovator

in Metal Making.

Purpose-Engineered

for Every Application

NSK rolling bearings for the steel and metal industry are expressly designed to endure and perform beyond conventional thinking in a uniquely punishing life. Heavy loads and staggering shock loads. Intense heat. High speeds, ultra-low speeds and rapid transitions between. Contamination from mill scale and water vapor. The challenges are diverse and considerable, but as a result of intense product development and collaboration with our customers, NSK delivers optimal bearing solutions from iron and steel making right up to the final rolled product.

Learn more about how NSK can help accelerate output and drive total cost efficiency.

Furnaces

Unimaginable radiant heat, massive loads, and slow, small ranges of motion exert punishing forces on bearings supporting basic oxygen and electric arc furnaces. Failure at this stage can bring everything downstream to a halt with the prospect of considerable maintenance downtime. Learn how NSK delivers application-optimized solutions that mitigate lost production and maintenance burdens.

Basic Oxygen Furnaces

Electric Arc Furnaces

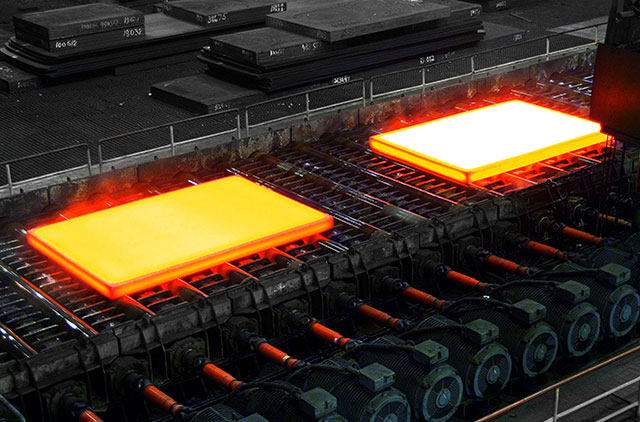

Continuous Casting

Ultra-low speeds, heavy loads, roll deflection and ever-present contamination present significant wear-related challenges to bearing performance in casting plants. Unplanned stoppage here is costly – in maintenance and replacement – and potentially impacts all downstream operations. Learn how NSK optimizes bearing operating life and extends maintenance intervals.

Ladle Turrets

Smooth, reliable ladle operation is achieved with highly specialized bearing solutions and maintenance strategies to manage bearing performance and safe casting efficiency.

Segment Rolls

Advanced material and design technologies overcome punishing mechanical and environmental operating conditions to effectively support reliable roll operation.

Run Out Tables

Best-fit solutions with dimensional stability under high heat as well as sealing and lubrication options to mitigate contamination and alleviate maintenance burden.

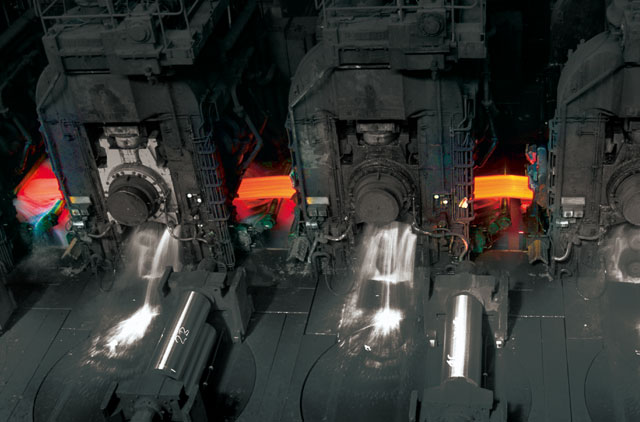

Rolling Mills

Learn how NSK applies bearing technology to endure the relentless punishment of high heat, heavy and impact loads, variable speeds with rapid accelerations, and the constant presence of cooling water with high capacity bearing solutions that drive output, reduce bearing and grease consumption, and increase total cost-efficiency.

Hot Rolling – Strip

Innovative, high capacity and cost-effective bearing solutions designed to withstand heavy and impact loads in water- and contaminant-laden operating environments.

Hot Rolling – Bar and Wire

High output with greater dimensional consistency is achieved with reliable bearing performance under intense heat, loads and speeds. Continuously. Without failure.

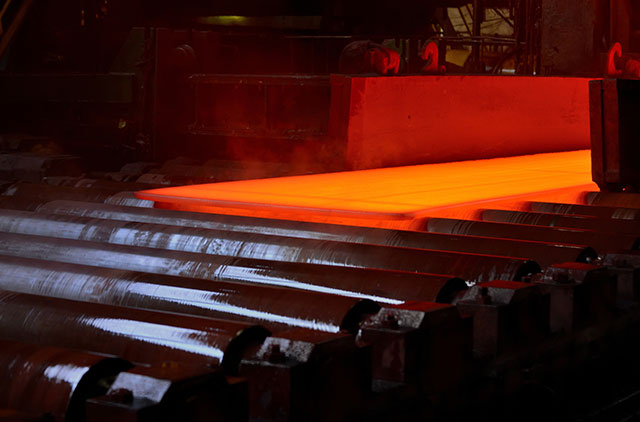

Cold Rolling

Accommodating heavy rolling loads with high rotational accuracy to support stringent material quality and finish with precise dimensional consistency of rolled steel.

Process Equipment

Optimal plant output can only be achieved when all rotating machinery and equipment runs smoothly and efficiently. Unplanned incidents here are intolerable but could be prolific in the absence of appropriate bearing and bearing supplier selection. Learn how NSK high-performance bearings outperform and outlast conventional expectations.

Overhead Cranes

For the powerlifters that keep mill processes in motion, radial loads are immense, exposure to heat and contamination is constant, and reliable bearing operation is crucial.

Conveyors

Keep the motion systems of metal making in continuous operation upstream and down, with bearings to support smooth and reliable material handling.

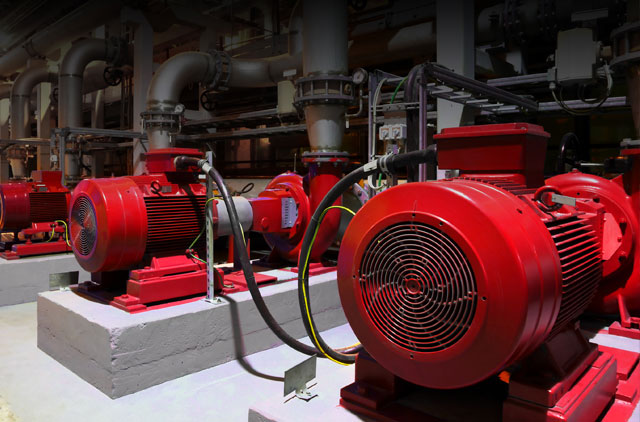

Motors, Pumps and Drives

Rotating process equipment, operating non-stop to keep mills running at peak capacity, demand high performance bearings that run harder, faster, smoother and longer.

MORE

MORE