Rolling Mills

Cold Rolling

Consistent Output

and Quality

Cold rolling is a demanding process – not only as a result of severe mechanical and operating environment stresses, but also due to the demands for increased throughput, stringent material quality and finish, high dimensional consistency, increased energy efficiency, and maximum machine uptime.

To accommodate, NSK work roll bearings deliver maximum performance, durability and service life through advanced material, seal and lubrication technologies. For optimized precision of cold-rolled steel, NSK back-up bearings for rolling stands and cluster mills accommodate heavy rolling loads while running with high rotational accuracy.

Application-Optimized Solutions

For the heavy rolling loads in back-up rolls in rolling mill stands, NSK Super-TF Four-Row Cylindrical Roller Bearings equipped with stud-type cages and solid rollers optimize load carrying capacity and minimize risk of roller damage.

Bearing Products

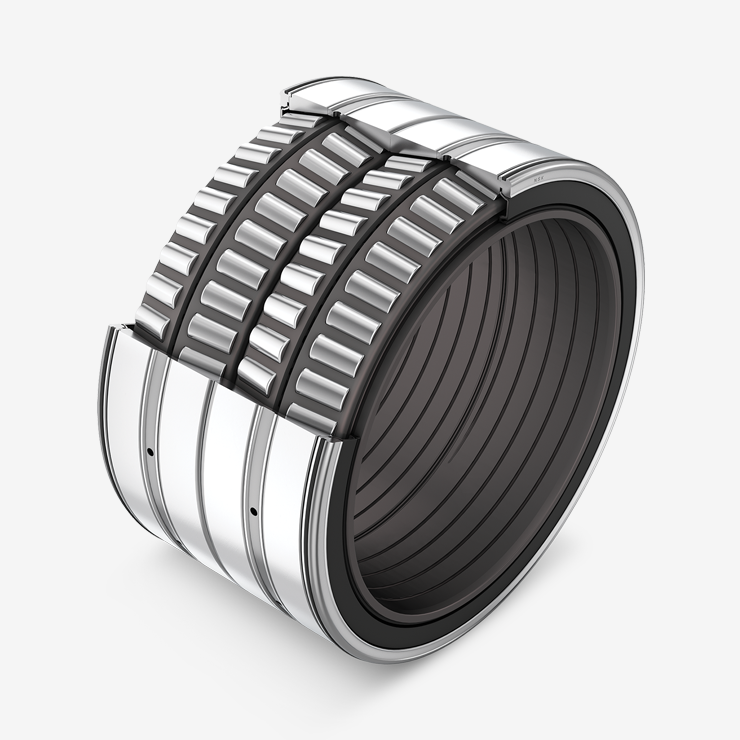

Four-Row Tapered Roller Bearings

Featuring NSK’s Sealed-Clean design for improved heat- and water-resistant protection.

Four-Row Cylindrical Roller Bearings

Accommodate extremely heavy and impact loads – while running with high rotational accuracy.

Double-Row Tapered Roller Bearings

Withstand heavy radial loads and thrust load support in back-up rolls.

Sendzimir Back-Up Roll Bearings

With heavy-load strength and running accuracy to support precise plate and sheet making.

Super-TF Steel Technology

Delivers superior resistance to wear, seizure and heat in contaminated operating environments.

Long-Life Water-Resistant Grease

With advanced properties to repel water and prevent lubricant deterioration.

Literature

|

Super-TF Sealed-Clean Four-Row Tapered Roller Bearings

|

|

Super-TF Four-Row Cylindrical Roller Bearings

|

|

Sendzimir Back-Up Roll Bearings

|

|

Long-Life Water-Resistant Bearing Grease

|

|

Roll Neck Bearing Manual

|

Case Studies

|

Cold Rolling Mill – Steel Strip

|

|

Cold Rolling Mill

|

|

Pipe Forming Roll

|

|

Pilger Mill

|

|

Continuous Annealing Process Line

|

|

Cold Form Saw for Steel Tube

|

MORE

MORE