Furnaces

BOF and EAF

Handling Extreme Loads

Safely and Reliably

From the outset of the metal-making process, sequencing, timing and reliable motion are critical. In furnaces and converters, at temperatures exceeding 2,500ºF, thousands of tons of molten steel moving slowly and precisely in stages of limited rotation impose severe mechanical forces on supporting bearings. Any performance issues here could potentially shut down the entire mill.

NSK bearing solutions for furnaces and converters are application-optimized, engineered to operate with stability at high temperatures, accommodating heavy loads, low speeds and oscillating motion with predictably reliable efficiency.

Application-Optimized Solutions

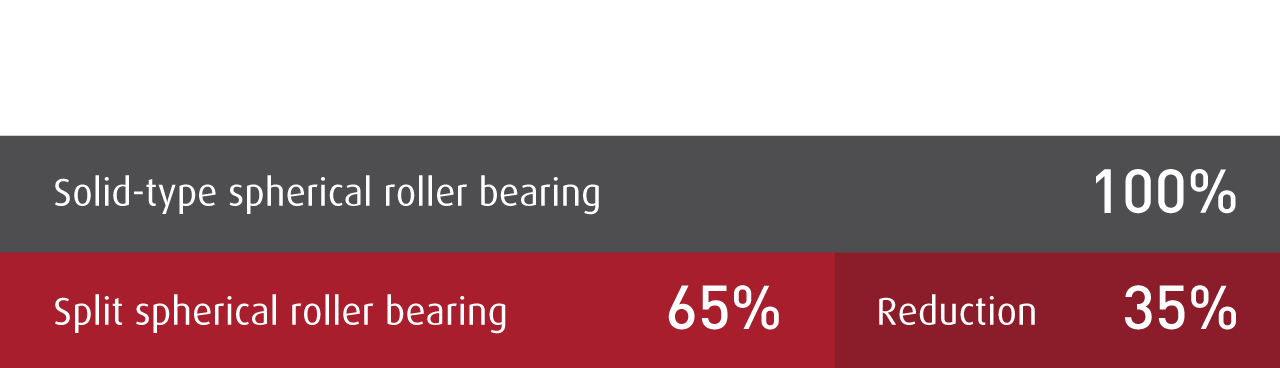

Eliminate removing bull gears and dismantling drives and surrounding equipment. With NSK Ultra-large Split Roller Bearings, replacement time, maintenance costs and

production loss is reduced – considerably.

Bearing Products

Ultra-Large Split Spherical Roller Bearings

Eliminate removing gears and dismantling drives for reduced replacement time, maintenance costs and production loss.

Large CAM Spherical Roller Bearings

Extremely high loads. Extreme speeds and high heat. Extreme reliability wherever unexpected downtime is intolerable.

Slewing Ring Bearings

Transferring very high forces to support radial, axial and moment loads with repeatedly reliable motion.

MORE

MORE