Continuous Casting

Run Out Tables

Reliable Running

Under High Heat

The end of the casting process presents unique challenges to the bearings supporting each roll in the run out tables. Intense radiant heat and heavy loads are inflicted by cast slabs moving at very low speeds. Water sprayed for cooling of bearing housings presents risk of moisture ingress. Maintaining appropriate bearing lubrication under these conditions can be constant and costly.

NSK offers a range of best-fit solutions for run out tables, with bearings and housings possessing the requisite dimensional stability under high heat as well as sealing and solid-lubrication options to mitigate contamination and alleviate maintenance burden.

Application-Optimized Solutions

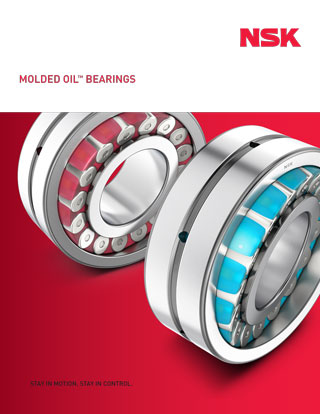

With a self-sustained continuous supply of clean lubricant to eliminate the need for relubrication and reduce ongoing maintenance, NSK Molded-Oil™ Bearings are an Ideal solution when access is restricted and uptime is essential.

Bearing Products

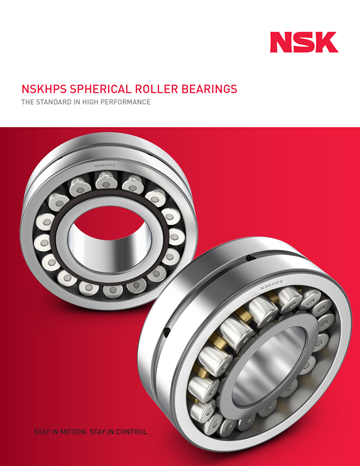

NSKHPS Spherical Roller Bearings

Designed to outperform and outlast, delivering higher load capacities, high speeds, and long-life performance.

Sealed Spherical Roller Bearings

Delivering longer bearing life under harsh and contaminated conditions while promoting a clean working environment.

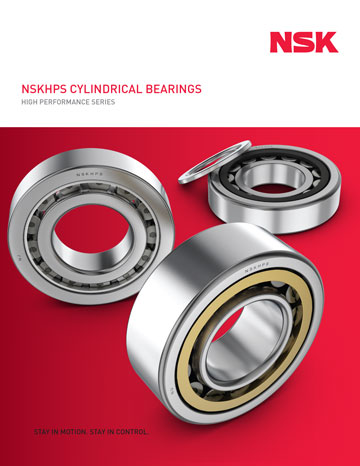

NSKHPS Cylindrical Roller Bearings

High strength and rigidity for high loads and superior roller guidance for smooth and reliable high-speed operation.

Literature

|

NSKHPS Spherical Roller Bearings

|

|

NSKHPS Cylindrical Roller Bearings

|

|

SAF Series Pillow Blocks

|

|

SNN Series Pillow Blocks

|

|

Molded-Oil Bearings

|

MORE

MORE