Advanced Product Solutions

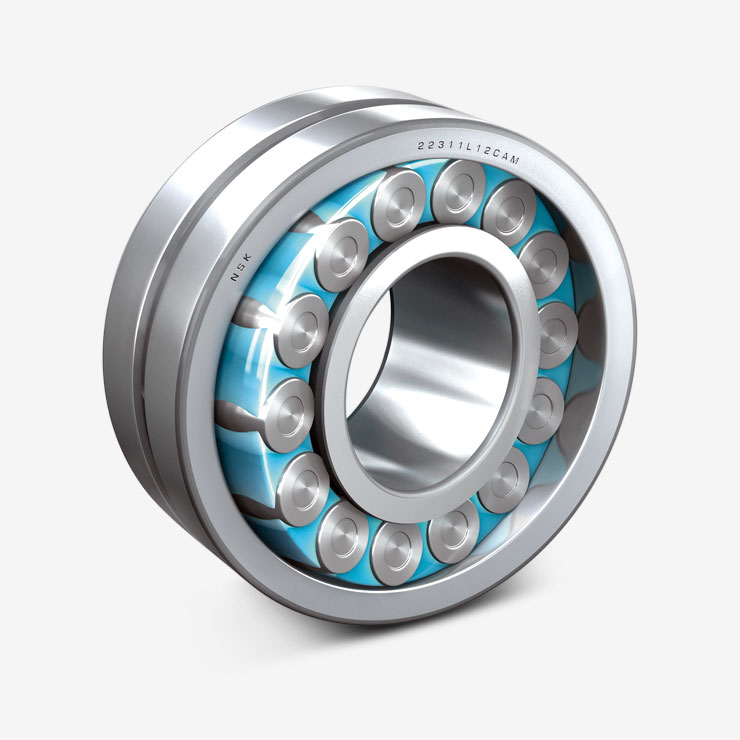

Molded-Oil™

Bearings

NSK Molded-Oil bearings are uniquely designed to prevent the ingress of contamination from detrimentally impacting bearing performance, while providing a continuous and clean source of lubrication to the bearing. Oil-impregnated polyolefin resin serves as a barrier to water and dust, and slowly releases ample lubrication to the bearing with minimal risk of oil leakage for an extended maintenance-free service life and reduced operating costs.

Proven Advantages

|

Extended maintenance-free performance with continuous supply of clean lubricant |

|

Eliminates the need for relubrication, reducing maintenance costs |

|

Eliminates risk of grease leakage, promoting clean operating environments |

|

More than 2x the operating life of grease lubricated bearings in water or dust-contaminated environments |

|

Ideal solution for remote or restricted access areas |

Spherical roller bearings for general and high-speed operation |

Tapered roller bearings for general operation |

Deep groove ball bearings for general and high-speed operation |

DESIGN FEATURES

|

Lubricated with oil-impregnated material (solid lube) consisting of lubricating oil and polyolefin resin |

|

Oil slowly seeping from this material provides ample lubrication to the bearing for extended periods |

|

Acts as a barrier to water and dust ingress |

|

Low torque for smooth rotation of rolling elements |

|

Compositions for both general and high-speed use |

|

Available for spherical roller, tapered roller and deep groove ball bearings |

Additional Solid Lube Options

|

Extreme temperatures, with solutions for temperatures ranging from as low as -50°F to as high as 350°F |

|

Heavy loads with low speeds, with high-viscosity oil to accommodate heavily loaded roller bearings |

|

Food-grade solutions, including suitability for incidental food contact and food processing |

|

High temperature wash-down applications |