Technical Support

Application Engineering

Technical Insights from

Design to Diagnostics

Proper bearing selection can have a major impact on a customer’s entire business, helping to achieve improvements in machine reliability, productivity and performance, all of which carry a tangible and measurable cost benefit. Identifying optimal solutions is an expertise of NSK’s application engineers, who work hand-in-hand with our customers from the original machine design stage to the resolution of performance issues.

With a foundation of industry, machine, and operating condition experience, NSK application engineers support our customers with a range of services including:

|

Application reviews |

|

Machine design support |

|

OEM part conversion |

|

Diagnostics |

|

Bearing condition analysis |

|

Failed bearing analysis |

|

Lubrication analysis |

|

TECHNICAL TOOLS

For the technically self-sufficient and independent problem-solver, NSK offers extensive online resources to facilitate design, selection and trouble-shooting, including:

|

Bearing selection catalog (including app) |

|

CAD file download |

|

Bearing calculation tools (including app) |

|

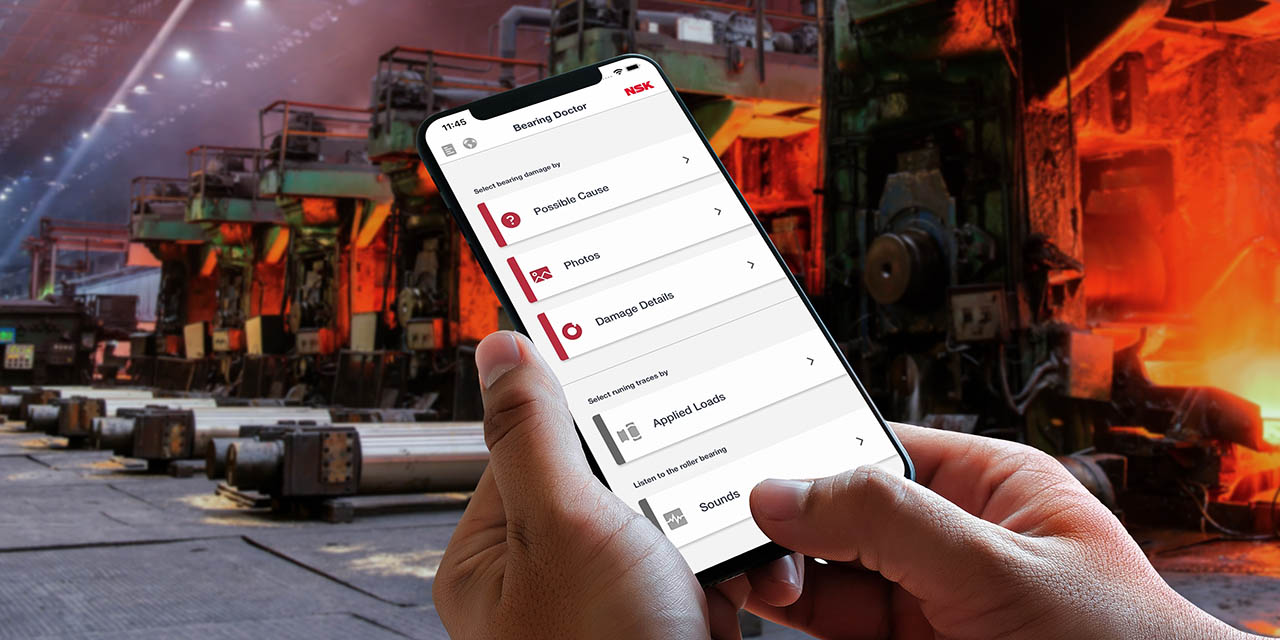

Troubleshooting (Bearing Doctor) app |

NSK Web Tools and Apps

Bearing Selection

NSK Bearing Catalog

Our interactive catalog helps you to select the correct bearings that best meet the dimension and operating performance requirements of your application and equipment.

NSK Bearing Calculation Tools

Calculate bearing life, recommended fits and clearances, frequencies, lubrication viscosities and relubrication intervals, frictional moment and speeds with NSK NAVI-FOCUS.

NSK Bearing CAD Models

Select your bearing type, validate suitability of dimensional and performance criteria, and download the CAD model to incorporate into your machine and equipment design.

Bearing Performance

NSK Bearing Doctor

Engage and interact to diagnose bearing damage and possible causes while discovering handling and maintenance practices to avoid bearing failure and unplanned downtime.

AIP Cost-Savings Calculator

Quantifiable improvement is derived from reduced bearing usage, maintenance costs and lost production. Calculate the total attainable cost savings from an NSK recommended solution.

AIP Cost-Benefit Calculator

Improvement may require short-term investment to achieve long-term efficiency gains. Calculate the break-even point where an NSK solution begins to yield cost benefits.

Literature

|

AIP - Added Value Program

|

|

Bearing Doctor

|

|

Bearing Maintenance Guide

|

|

Bearing Maintenance Tools

|

|

NSK Reconditioning Program

|

|

Roll Neck Bearing Manual

|

Visit Online

Visit Online