Technical Support

Maintenance Tools

Expert Tools.

From the Experts.

Bearings are a key precision component in any moving machinery and must be handled carefully to ensure they perform to their full potential. Bearings have to be correctly fitted, both onto a shaft and into a housing, as recommended by NSK in our technical catalogs. Consequently, fitting a bearing requires special tools and equipment: from safely heating components to safely applying appropriate forces to achieve assembly. Not observing these practices can lead to damage to a bearing or surrounding parts, premature failure and unnecessary maintenance costs.

NSK offers a complete range of specialist tools to ensure bearings are fitted and removed without damage. This is complemented by available NSK training courses that teach best practice in using these tools and help engineers to develop safe and efficient assembly procedures.

|

|

Mounting Tools

NSK’s range of bearing tools ensures that all components are handled correctly without damage. Having the correct tools for the job ensures that machines are assembled and dismantled correctly and efficiently.

|

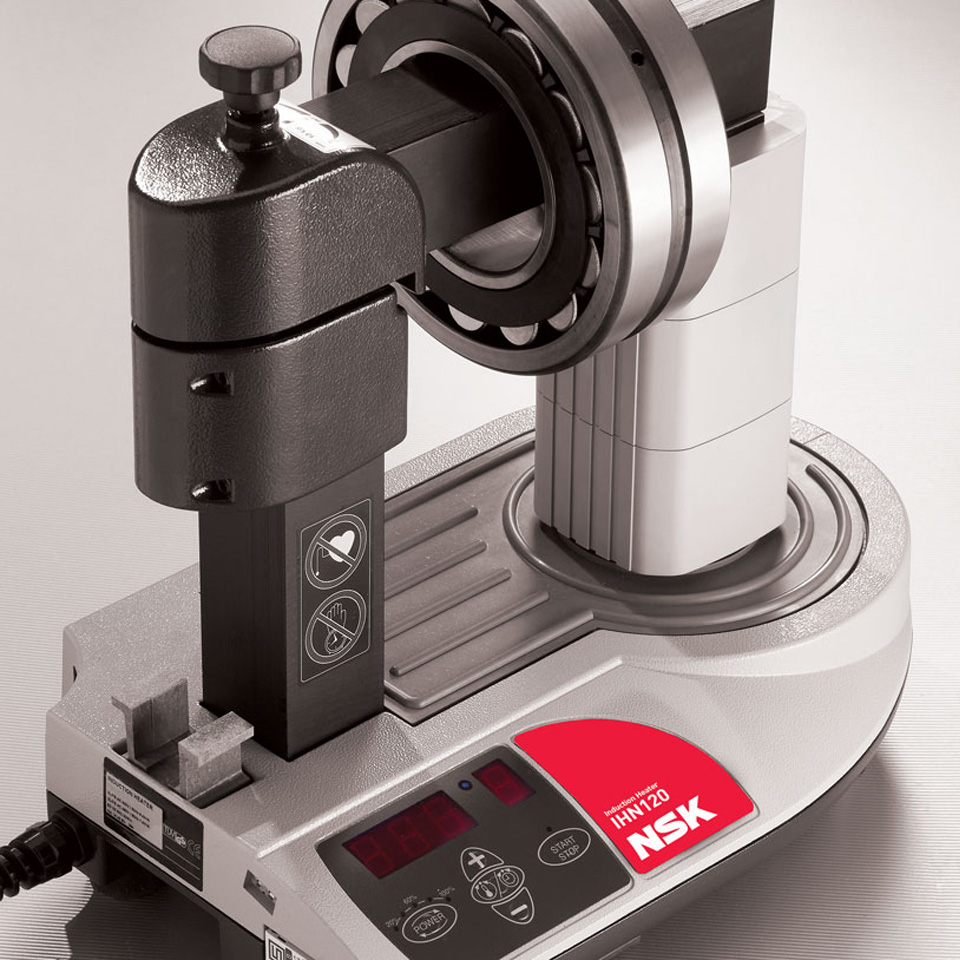

Induction heaters |

|

Fitting tool kit |

|

Bearing puller kit |

|

Spanner wrenches |

|

Sine bars |

|

Hydraulic pullers and pushers |

|

Tri-section press plates |

|

Hydraulic nuts |

|

Hydraulic pumps |

|

|

Laser Alignment

Accurate alignment of rotating machinery components is extremely important for correct operation and optimum power usage, while preventing early wear and failure of components such as bearings, gears, seals and couplings.

NSK’s laser alignment equipment includes devices for both shaft and belt drive systems:

|

Laser shaft alignment tool |

|

Laser belt alignment tool |

NSK Web Tools and Apps

Bearing Selection

NSK Bearing Catalog

Our interactive catalog helps you to select the correct bearings that best meet the dimension and operating performance requirements of your application and equipment.

NSK Bearing Calculation Tools

Calculate bearing life, recommended fits and clearances, frequencies, lubrication viscosities and relubrication intervals, frictional moment and speeds with NSK NAVI-FOCUS.

NSK Bearing CAD Models

Select your bearing type, validate suitability of dimensional and performance criteria, and download the CAD model to incorporate into your machine and equipment design.

Bearing Performance

NSK Bearing Doctor

Engage and interact to diagnose bearing damage and possible causes while discovering handling and maintenance practices to avoid bearing failure and unplanned downtime.

AIP Cost-Savings Calculator

Quantifiable improvement is derived from reduced bearing usage, maintenance costs and lost production. Calculate the total attainable cost savings from an NSK recommended solution.

AIP Cost-Benefit Calculator

Improvement may require short-term investment to achieve long-term efficiency gains. Calculate the break-even point where an NSK solution begins to yield cost benefits.

Literature

|

AIP - Added Value Program

|

|

Bearing Doctor

|

|

Bearing Maintenance Guide

|

|

Bearing Maintenance Tools

|

|

NSK Reconditioning Program

|

|

Roll Neck Bearing Manual

|

Visit Online

Visit Online