NSK Case Study

Application

Air Recirculation Fan

Cost Savings: $415,546

A customer was experiencing bearing failure on an Air Recirculation Fan application within an ore preparation plant. This had been a regular problem. Compressed air cooling was applied to try and reduce the bearings’ high running temperature. NSK Engineers conducted an Application Review including a temperature survey of the fan and bearings, revealing major issues with incorrect fitting of the bearings, over-lubrication and inadequate sealing arrangement. NSK recommended using NSKHPS Spherical Roller Bearings within NSK SNN Pillow Blocks and NSK Labyrinth seals. In addition, recommendations were given for correct fitting and correct lubrication intervals and amounts. A trial was conducted resulting in no bearing failure for more than 12 months. The compressed air cooling was also removed, adding additional savings.

Key Facts

|

Air recirculation fan application |

|

High bearing temperatures in operation |

|

Extraordinary measures – compressed air – required to countermeasure temperature rise |

|

Incorrect fitting, lubrication amounts and frequencies |

Air Recirculation Fan

Value Proposals

|

NSK engineering conducted an Application Review including a Temperature Survey and a Bearing Condition Report |

|

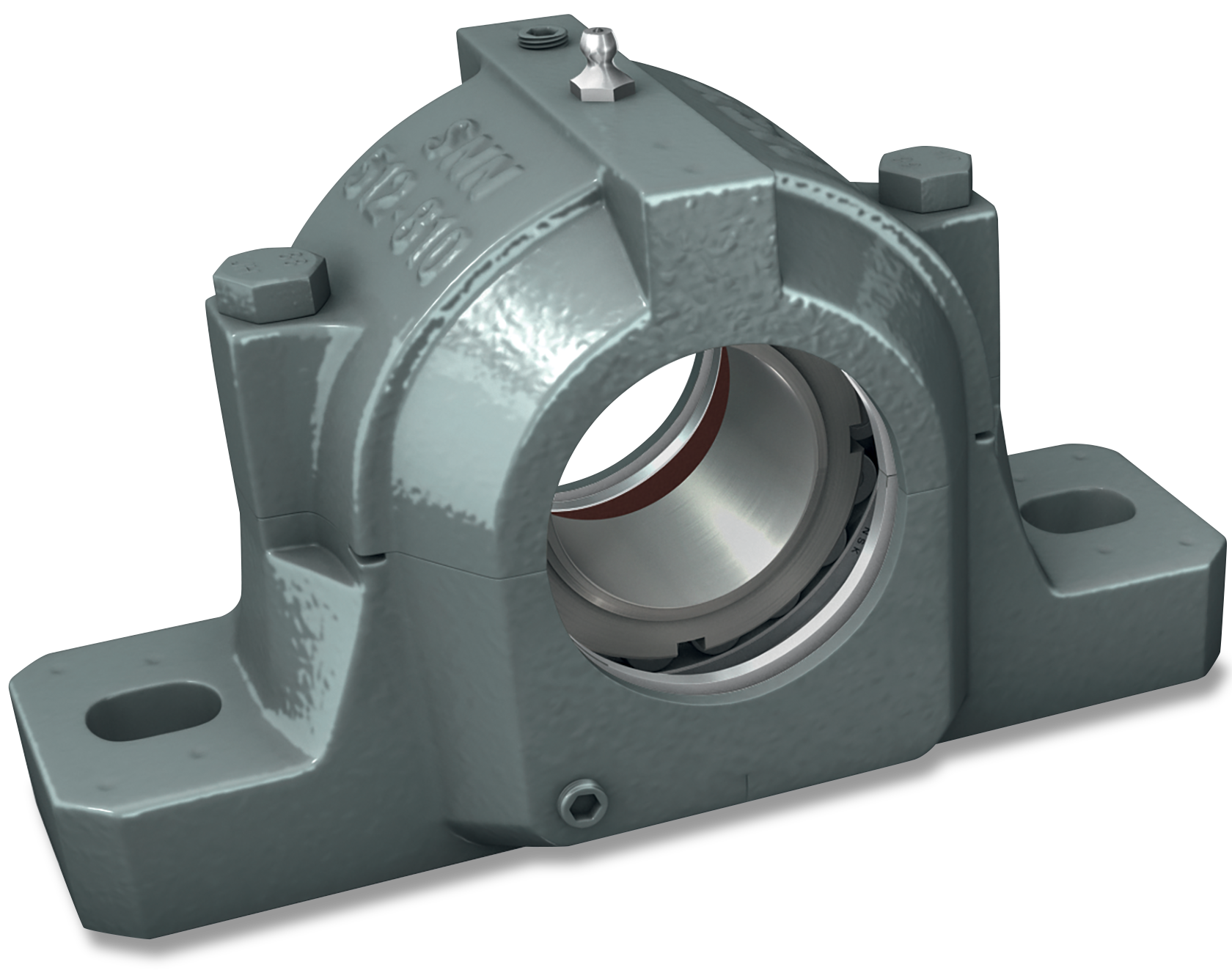

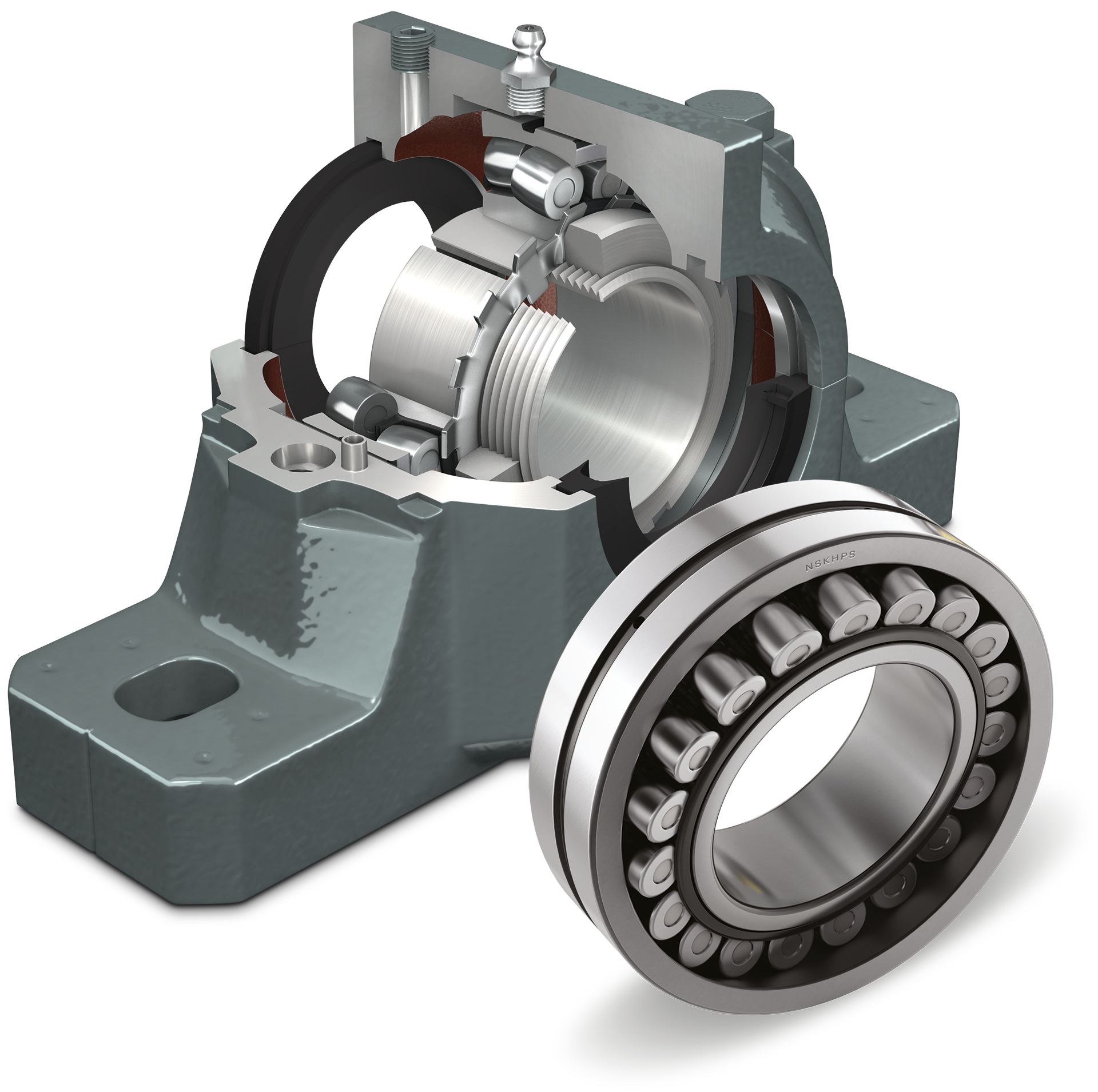

NSK engineers recommended NSKHPS Spherical Roller Bearings in combination with SNN Pillow Blocks and Labyrinth seals and suggested changes in the lubrication amounts and intervals |

|

Trial conducted, with NSK Engineering overseeing the installation and implementation of NSK recommendations |

|

The customer benefited from increased productivity, reduced maintenance costs and the removal of compressed air resulting in a significant cost savings |

Product Features

|

Manufactured from grade 200 cast iron |

|

High precision bore for optimum bearing seating |

|

Split block design allows for easy mounting and dismounting of pre-assembled shafts |

|

Available for shaft diameters from 20 to 140 mm and/or 3/4” to 5 1/2” |

|

Threaded lubrication hole(s) on the cap and 1 drainage outlet on the base |

|

Dimples on the housing surface facilitate additional holes for sensors, lubrication, mounting bolts or locating pins |

|

Large oil bath to maximize oil change intervals |

|

Good heat transfer |

|

Contact and non-contact seal options |

NSKHPS Spherical Roller Bearing

Cost-Savings Breakdown

| Before | Cost | NSK Solution | Cost | |||

|---|---|---|---|---|---|---|

| $9,002/hour x 36 hours downtime due to bearing failure | $324,072 | No downtime | $0 | |||

| $45/hr x 36 hours x 2 persons due to bearing failure | $3,240 | Manpower, fitting of NSK bearing $45/hr x 8 hours x 2 persons | $720 | |||

| Compressed air | $88,954 | Removal of compressed air | $0 | |||

| Bearing | $804 | Bearing | $804 | |||

| Total Costs | $417,070 | Total Costs | $1,524 | |||

| Before | Cost | |

|---|---|---|

| $9,002/hour x 36 hours downtime due to bearing failure | $324,072 | |

| $45/hr x 36 hours x 2 persons due to bearing failure | $3,240 | |

| Compressed air | $88,954 | |

| Bearing | $804 | |

| Total Costs | $417,070 | |

| NSK Solution | Cost | |

|---|---|---|

| No downtime |

$0 | |

| Manpower, fitting of NSK bearing $45/hr x 8 hours x 2 persons | $720 | |

| Removal of compressed air | $0 | |

| Bearing | $804 | |

| Total Costs | $1,524 | |

Your Partner for Machine Optimization

Our AIP Added Value Program is based around a simple proposition: ‘improvement pays’. By working with you throughout the AIP Value Cycle, we will help you achieve improvements in machine reliability, productivity and performance, all of which carry a tangible and measurable cost benefit – and we have the tools to prove it! That’s what we mean by improvement pays.

PDF Download

PDF Download