NSK Case Study

Application

Continuous Casting Machine

Cost Savings: $15,922

A steel maker was experiencing problems with their continuous casting machine. The life of a roll segment Cylindrical Roller Bearing was only one to two months. The casting machine had a very complicated cooling and lubricating piping system. The mill was realizing significant maintenance costs due to the complexity of reconnecting the piping system. NSK proposed to assemble the rollers of one segment with Sealed Spherical Roller Bearings equipped with high-temperature grease. The suggested changes offered significant improvements in bearing performance and reduced maintenance cost.

Key Facts

|

Continuous casting machine |

|

Long replacement time for Cylindrical Roller Bearing with oil lubrication due to complicated piping system |

|

NSK Solution: Sealed Spherical Roller Bearings |

|

Significant increase in operating life / reduced maintenance downtime and associated costs |

|

Eco-friendly, sealed-clean bearing operation |

|

Eco-friendly due to lack of contamination from equipment |

|

Reduction in maintenance time and cost |

Continuous Casting Machine

Value Proposals

|

NSK analyzed the application and proposed to install Sealed Spherical Roller Bearings in a trial segment |

|

With the new bearings, dismantling and re-installation of the oil piping system was eliminated |

|

Eco-friendly system reduced oil consumption; bearings pre-filled with high-temperature grease |

|

Bearing replacement was reduced from 20 hours to 10 |

|

Bearing operating life was increased from 2 to 4 months |

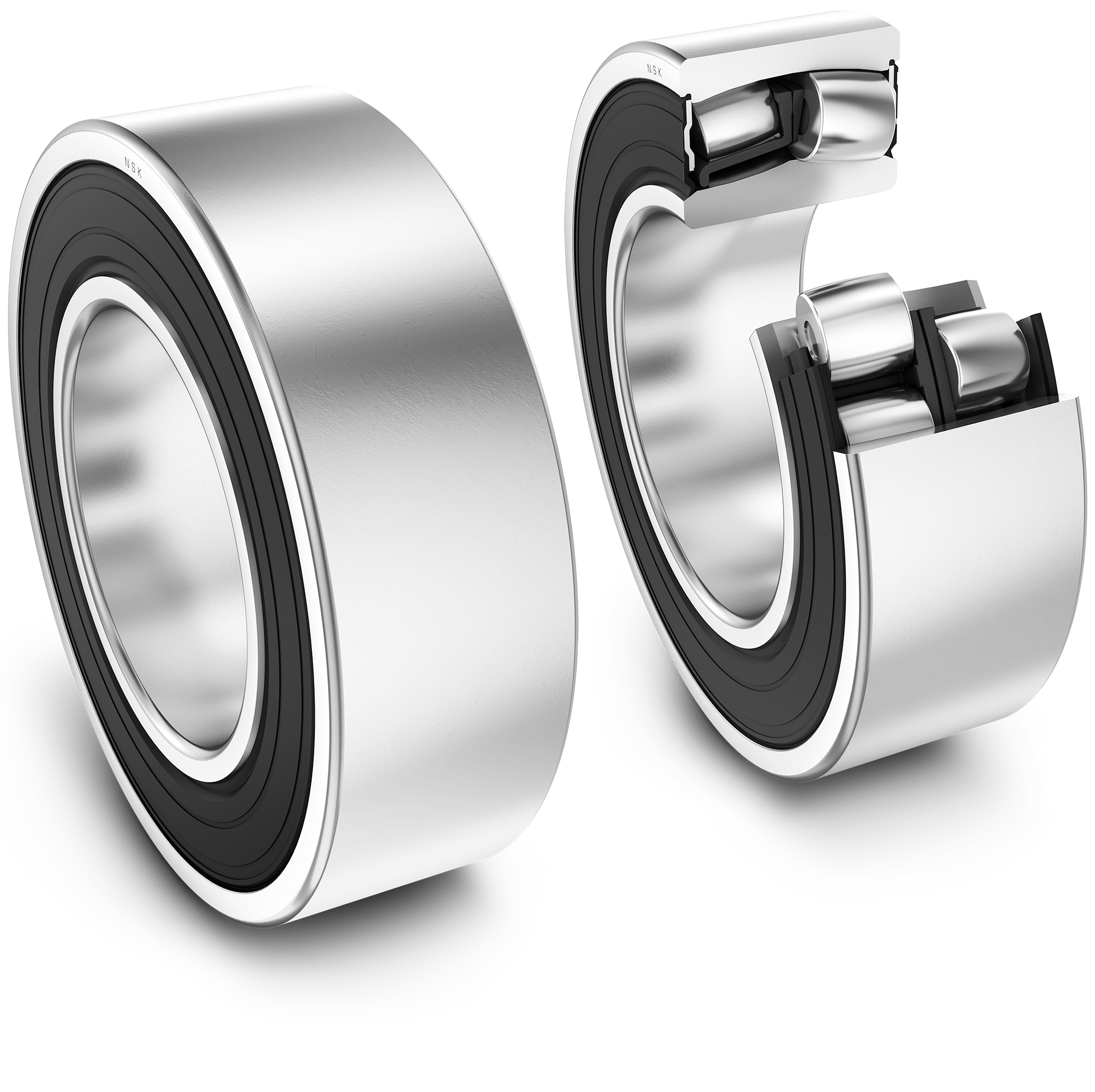

Product Features

|

Special “outward-extending, spring-loaded lip seal” |

|

Nitride rubber seal – or differing seals depending on temperature needs |

|

Special long-life grease: heat and pressure resistant |

|

Symmetrical roller and raceway design to prevent edge loading problems |

|

Special chamfer configuration for smooth axial movement |

|

Seal retains grease, offering longer running time with improved efficiency |

|

Reduction in grease consumption and no leaks due to special seal provides cleaner working environments |

|

Increased uptime |

Sealed Spherical

Roller Bearing

Roller Bearing

Cost-Saving Breakdown

| Before | Cost | NSK Solution | Cost | |||

|---|---|---|---|---|---|---|

| 6 Sets of bearings per segment per year | $27,016 | 3 Sets of bearings per segment per year | $30,393 | |||

| 6 replacement intervals per year, 20 hours per replacement (including dismantling and re-installation of the oil piping system) | $32,162 | 3 replacement intervals per year, 10 hours per replacement | $12,863 | |||

| Total Costs | $59,178 | Total Costs | $43,256 | |||

| Before | Cost | |

|---|---|---|

| 6 Sets of bearings per segment per year | $27,016 | |

| 6 replacement intervals per year, 20 hours per replacement (including dismantling and re-installation of the oil piping system) | $32,162 | |

| Total Costs | $59,178 | |

| NSK Solution | Cost | |

|---|---|---|

| 3 Sets of bearings per segment per year |

$30,393 | |

| 3 replacement intervals per year, 10 hours per replacement | $12,863 | |

| Total Costs | $43,256 | |

Your Partner for Machine Optimization

Our AIP Added Value Program is based around a simple proposition: ‘improvement pays’. By working with you throughout the AIP Value Cycle, we will help you achieve improvements in machine reliability, productivity and performance, all of which carry a tangible and measurable cost benefit – and we have the tools to prove it! That’s what we mean by improvement pays.

PDF Download

PDF Download