NSK Case Study

Application

Dust Extraction Fan

Cost Savings: $95,323

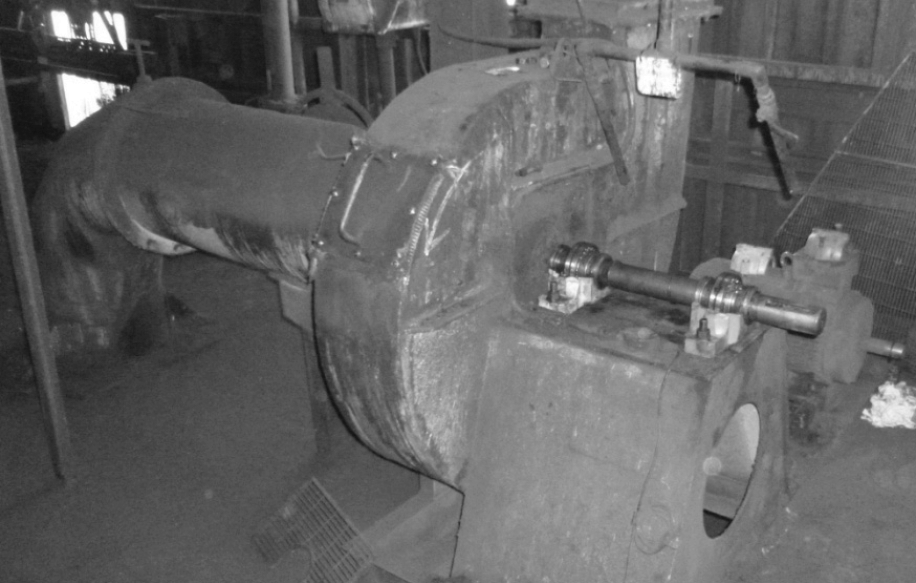

An ore preparation plant was experiencing high temperatures within a dust extraction fan. The bearing temperature was cooled down at considerable cost by using compressed air. NSK Engineering conducted an Application Review including a temperature survey revealing major issues with the sealing. Operating at high speed caused the seal lip to burn off and over-lubrication contributed to the high running temperature. NSK recommended using NSKHPS Spherical Roller Bearings with SNN Pillow Blocks and labyrinth seals, along with recommendations for correct lubrication intervals and amounts. A trial was conducted resulting in a considerable temperature reduction and significant cost savings by removal of the compressed air.

Key Facts

|

Dust extraction fan application |

|

High bearing temperatures in operation |

|

Extraordinary measures – compressed air – required to countermeasure temperature rise |

|

Incorrect lubrication amounts and frequencies |

Dust Extraction Fan

Value Proposals

|

NSK engineering conducted an Application Review including a Temperature Survey and a Bearing Condition Report |

|

NSK engineering recommended NSKHPS Spherical Roller Bearings in combination with SNN Pillow Blocks and labyrinth seals |

|

Modifications to lubrication amounts and intervals |

|

Trial conducted, with NSK Engineering overseeing the installation and implementation |

|

The customer benefited from increased productivity, reduced maintenance costs and the elimination of compressed air, resulting in a significant cost savings |

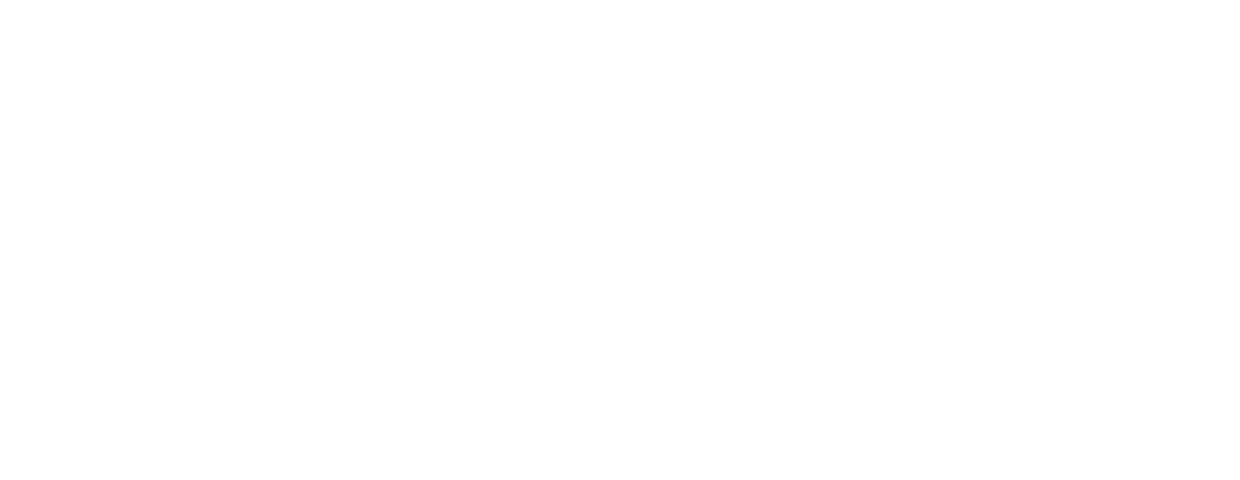

Product Features

|

Manufactured from grade 200 cast iron |

|

High precision bore for optimum bearing seating |

|

Split block design allows for easy mounting and dismounting of pre-assembled shafts |

|

Available for shaft diameters from 20 to 140 mm and/or 3/4” to 5 1/2” |

|

Threaded lubrication hole(s) on the cap and 1 drainage outlet on the base |

|

Dimples on the housing surface facilitate additional holes for sensors, lubrication, mounting bolts or locating pins |

|

Large oil bath to maximize oil change intervals |

|

Good heat transfer |

|

Contact and non-contact seal options |

SNN Pillow Block and

NSKHPS Spherical Roller Bearing

NSKHPS Spherical Roller Bearing

Cost-Savings Breakdown

| Before | Cost | NSK Solution | Cost | |||

|---|---|---|---|---|---|---|

| Compressed air to cool bearings | $95,323 | Eliminate need for compressed air | $0 | |||

| Total Costs | $95,323 | Total Costs | $0 | |||

| Before | Cost | |

|---|---|---|

| Compressed air to cool bearings | $95,323 | |

| Total Costs | $95,323 | |

| NSK Solution | Cost | |

|---|---|---|

| Eliminate need for compressed air |

$0 | |

| Total Costs | $0 | |

Your Partner for Machine Optimization

Our AIP Added Value Program is based around a simple proposition: ‘improvement pays’. By working with you throughout the AIP Value Cycle, we will help you achieve improvements in machine reliability, productivity and performance, all of which carry a tangible and measurable cost benefit – and we have the tools to prove it! That’s what we mean by improvement pays.

PDF Download

PDF Download