NSK Case Study

Application

Hot Strip Mill

Cost Savings: $165,088

A large steel manufacturer wanted to increase replacement intervals of Four-Row Tapered Roller Bearings used in the hot strip mill. Due to severe operating conditions, standard bearings provided only 1,400 hours of operation. The key target was to decrease spend on bearing replacement and maintenance. NSK inspected the bearing units along with the operating conditions. As a result new Super-TF Four-Row Tapered Roller Bearings with modified internal design and contact angle were delivered for testing. With the suggested solution, bearing lifetime was increased to 2,200 hours.

Key Facts

|

Four-Row Tapered Roller Bearings running only 1,400 hours before needing replacement |

|

Failures were causing frequent line stoppages |

|

NSK Solution: Super-TF bearings with modified internal design |

|

Increased bearing life – reduced bearing consumption, reduced downtime, reduced maintenance costs |

Finishing Section of Hot Strip Mill

Value Proposals

|

NSK engineers inspected the machine and operating conditions |

|

The Analysis showed that the existing bearing solution was not adequate for the application |

|

Due to the severe operating conditions, NSK recommended additional modification of the bearings internal design along with a suggested contact angle change |

|

Training was provided regarding root cause failure to prevent further issues |

|

The customer received increased bearing life and reduction in maintenance costs, bearing consumption and downtime |

Product Features

|

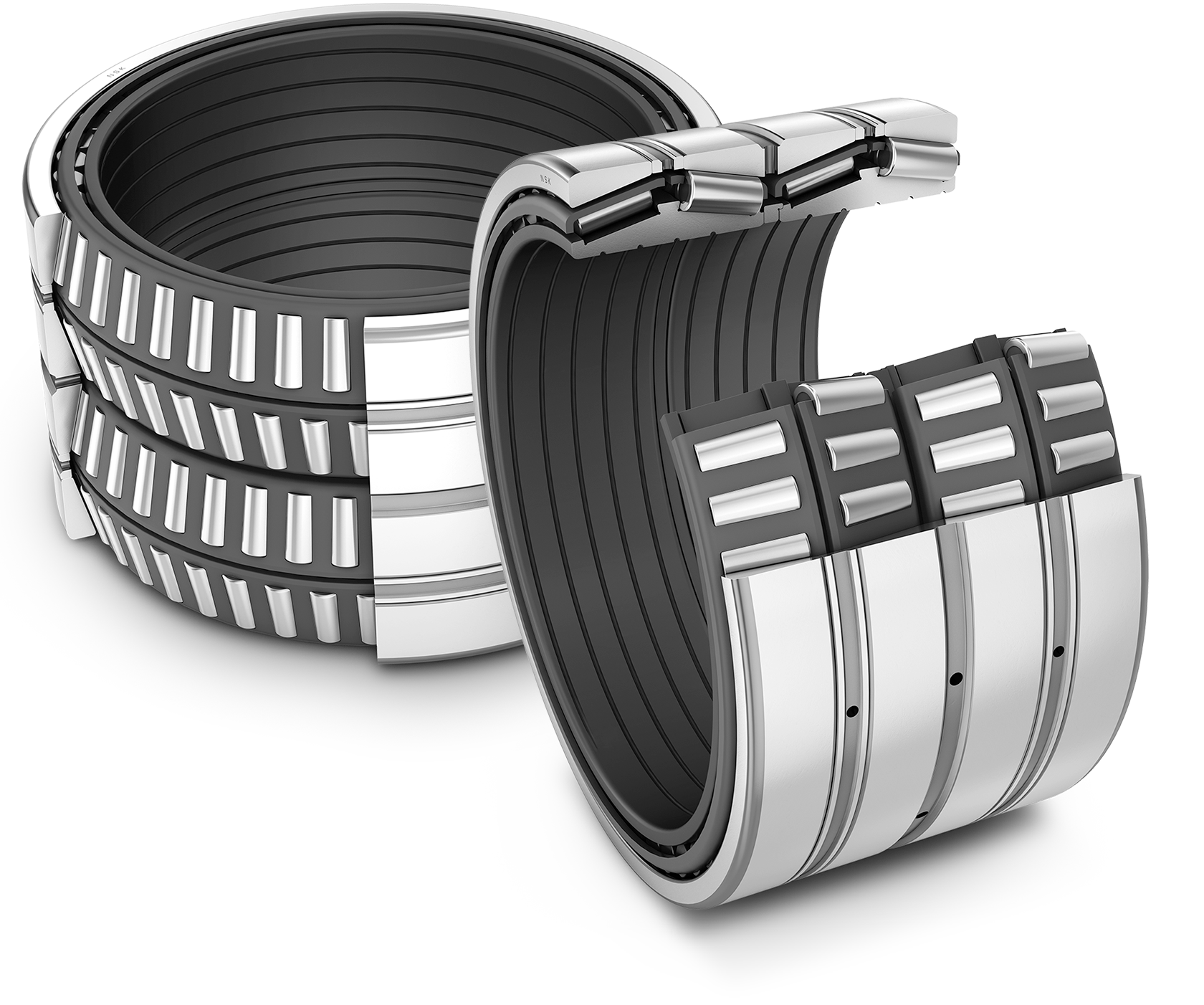

Advanced Super-TF material composition containing appropriate levels of chrome and molybdenum for increased hardness |

|

Innovative and patented heat treatment technology to optimize retained austenite and formation of finer carbide and carbonitride particles |

|

Significantly outperforms standard bearing steel in seizure resistance, rate of wear and service life |

|

Reduced non-metallic inclusions on raceway surface inhibiting the generation of surface cracks |

NSK Super-TF Four-Row

Tapered Roller Bearing

Tapered Roller Bearing

Cost-Savings Breakdown

| Before | Cost | NSK Solution | Cost | |||

|---|---|---|---|---|---|---|

| Bearing replacement | $463,105 | Bearing replacement | $308,737 | |||

| Additional maintenance incurred versus NSK solution | $10,720 | |||||

| Total Costs | $473,825 | Total Costs | $308,737 | |||

| Before | Cost | |

|---|---|---|

| Bearing replacement | $463,105 | |

| Additional maintenance incurred versus NSK solution | $10,720 | |

| Total Costs | $473,825 | |

| NSK Solution | Cost | |

|---|---|---|

| Bearing replacement |

$308,737 | |

| Total Costs | $308,737 | |

Your Partner for Machine Optimization

Our AIP Added Value Program is based around a simple proposition: ‘improvement pays’. By working with you throughout the AIP Value Cycle, we will help you achieve improvements in machine reliability, productivity and performance, all of which carry a tangible and measurable cost benefit – and we have the tools to prove it! That’s what we mean by improvement pays.

PDF Download

PDF Download