NSK Case Study

Application

Wire Forming Production

Cost Savings: $1,288,690

A customer was experiencing repeated bearing failures on their wire drawing machinery, resulting in excessive downtime and high maintenance costs. The financial impact was significant, and resolution was urgent. Upon investigation, NSK specialists determined that the root cause of bearing failure stemmed from sealing deficiencies and compromised lubrication. A new bearing and lubrication package was recommended and tested, with results demonstrating dramatically improved bearing performance and service life.

Key Facts

|

Continuous wire drawing process with high loads and arduous conditions |

|

High bearing failure rates, as many as 75 per month |

|

Excessive downtime and high maintenance costs |

|

Failure Analysis determination: compromised lubrication |

|

NSK proposed a sealed full complement Cylindrical Roller Bearing filled with a Lithium Complex grease |

|

Improved bearing performance / productivity achieved |

Wire Drawing Machine

Value Proposals

|

Bearing failure analysis indicated that the primary cause was poor lubrication |

|

Lubrication analysis determined that the existing graphite-based lubricant employed was not suitable |

|

NSK proposed a trial using a specially selected Lithium Complex grease together with a sealed full complement Cylindrical Roller Bearing |

|

Initial trials demonstrated a 40% increase in bearing life |

|

The customer converted all of their roll assemblies over to the NSK proposed bearing / grease combination |

|

A significant reduction in downtime and maintenance costs was achieved, resulting in a substantial cost savings |

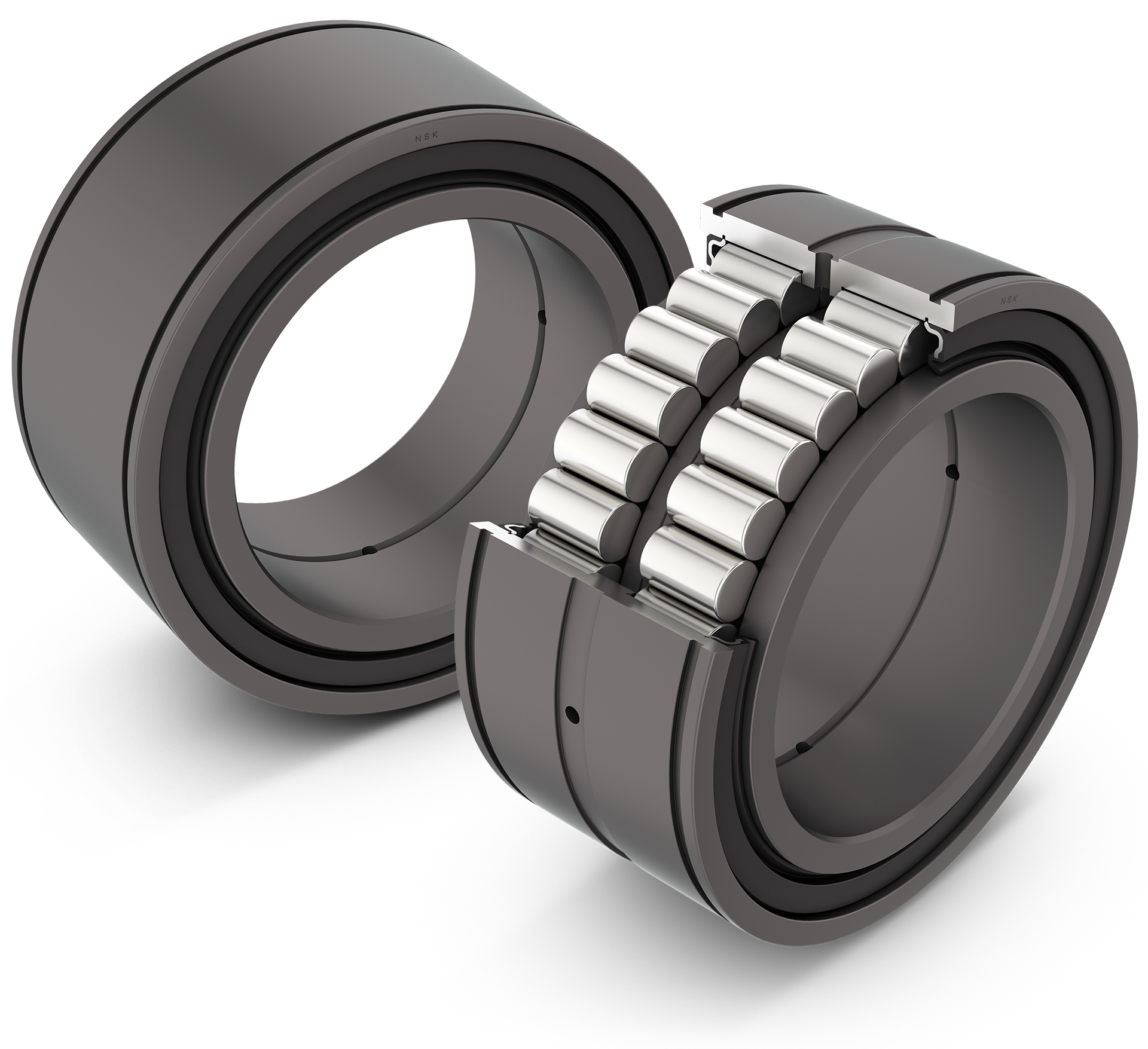

Product Features

|

Accommodates extremely high radial and axial loads |

|

Advanced contact seal prevents grease leakage and ingress of water and external contaminants |

|

Corrosion resistant phosphate coating permits use in a wide range of environments, including exposure to external environments |

|

Simple re-lubrication – even during operation – with inner and outer ring lubrication holes and grooves |

|

Bearings filled with Lithium Complex grease |

|

Can be fitted with snap rings on the outer ring |

Full complement

Cylindrical

Roller Bearing unit

with seals

Cylindrical

Roller Bearing unit

with seals

Cost-Savings Breakdown

| Before | Cost | NSK Solution | Cost | |||

|---|---|---|---|---|---|---|

| Constant failure of bearings / 75 Rolls changed per month |

Significant improved reliability / 45 Rolls changed per month |

|||||

| 0.5 hours per change / $6,428 per hour lost production / $241,042 per month x 12 months |

$2,892,504 | 0.5 hours per change / $6,428 per hour lost production / $144,585 per month x 12 months |

$1,735,020 | |||

| 378 labor hours / $14,983 per month x 12 months |

$179,796 | 108 labor hours / $4,279 per month x 12 months |

$51,348 | |||

| Technical Support & Engineering Time |

$2,758 | No Technical Support needed | $0 | |||

| Total Costs | $3,075,058 | Total Costs | $1,786,368 | |||

| Before | Cost | |

|---|---|---|

| Constant failure of bearings / 75 Rolls changed per month |

||

| 0.5 hours per change / $6,428 per hour lost production / $241,042 per month x 12 months |

$2,892,504 | |

| 378 labor hours / $14,983 per month x 12 months |

$179,796 | |

| Technical Support & Engineering Time |

$2,758 | |

| Total Costs | $3,075,058 | |

| NSK Solution | Cost | |

|---|---|---|

| Significant improved reliability / 45 Rolls changed per month |

||

| 0.5 hours per change / $6,428 per hour lost production / $144,585 per month x 12 months |

$1,735,020 | |

| 108 labor hours / $4,279 per month x 12 months |

$51,348 | |

| No Technical Support needed | $0 | |

| Total Costs | $1,786,368 | |

Your Partner for Machine Optimization

Our AIP Added Value Program is based around a simple proposition: ‘improvement pays’. By working with you throughout the AIP Value Cycle, we will help you achieve improvements in machine reliability, productivity and performance, all of which carry a tangible and measurable cost benefit – and we have the tools to prove it! That’s what we mean by improvement pays.

PDF Download

PDF Download