Advanced Product Solutions

Super-TF

Steel Technology

Durability – even in extreme operating environments – is a critical criterion for steel mill bearings. Reliable, uninterrupted performance of rolling components that endure heavy loads and high heat amid water and scale is critical to realizing and accelerating production capacities.

NSK’s Super-TF (STF) series bearings are designed to deliver outstanding durability in contaminated operating environments. Through advanced material engineering and heat treatment technology, they perform with superior resistance to wear, seizure and heat.

Super-TF bearings provide dramatically longer service life, optimize machine performance, reduce maintenance intervals and deliver total cost-efficiency.

Proven Advantages

|

As much as 10 times the service life of conventional carburized bearings in contaminated lubrication conditions |

|

More than 5 times the service life of conventional carburized bearings in boundary lubrication conditions |

|

Approximately 4 times the service life of conventional bearing steel at temperatures as high as 160°C |

|

Less than 1/3 the rate of wear compared to conventional bearing steel |

|

As much as 40% improvement in seizure resistance compared to conventional bearing steel |

|

Optimized bearing cost-efficiency, reduced maintenance intervals and increased total productivity |

Identification of Failure Mechanisms

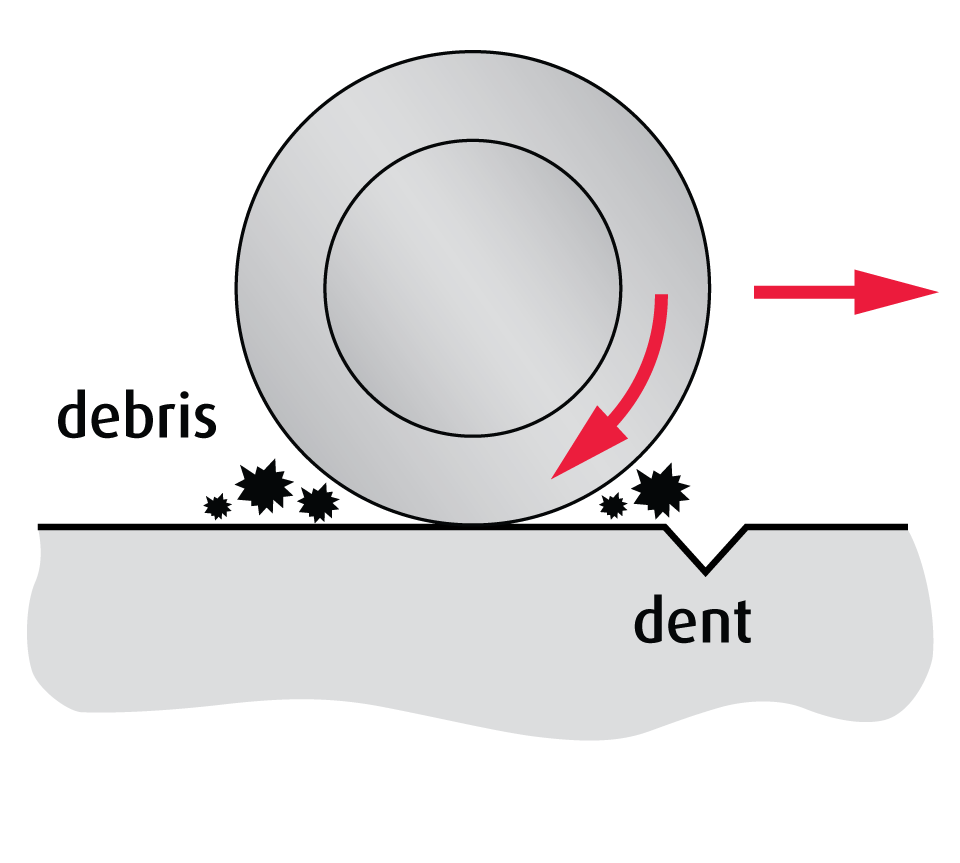

Stage 1: Surface Denting

Raceway surface dents occur due to foreign debris contamination

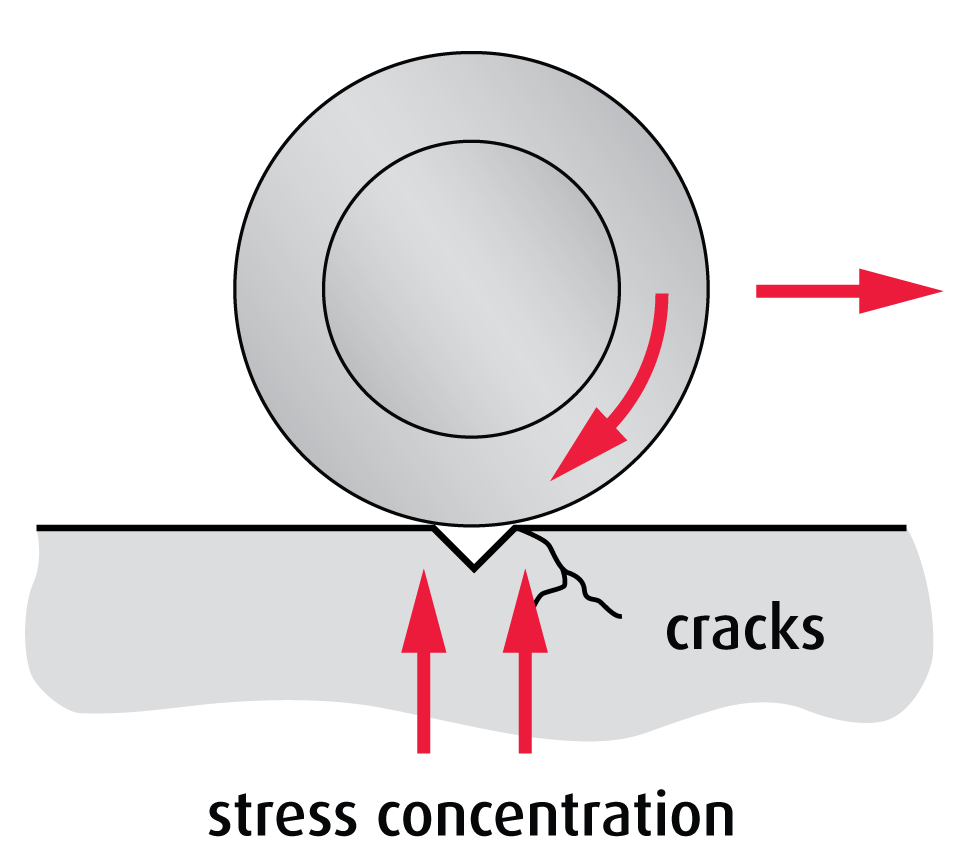

Stage 2: Crack Formation

Stress concentration around the debris causes dents to develop into cracks

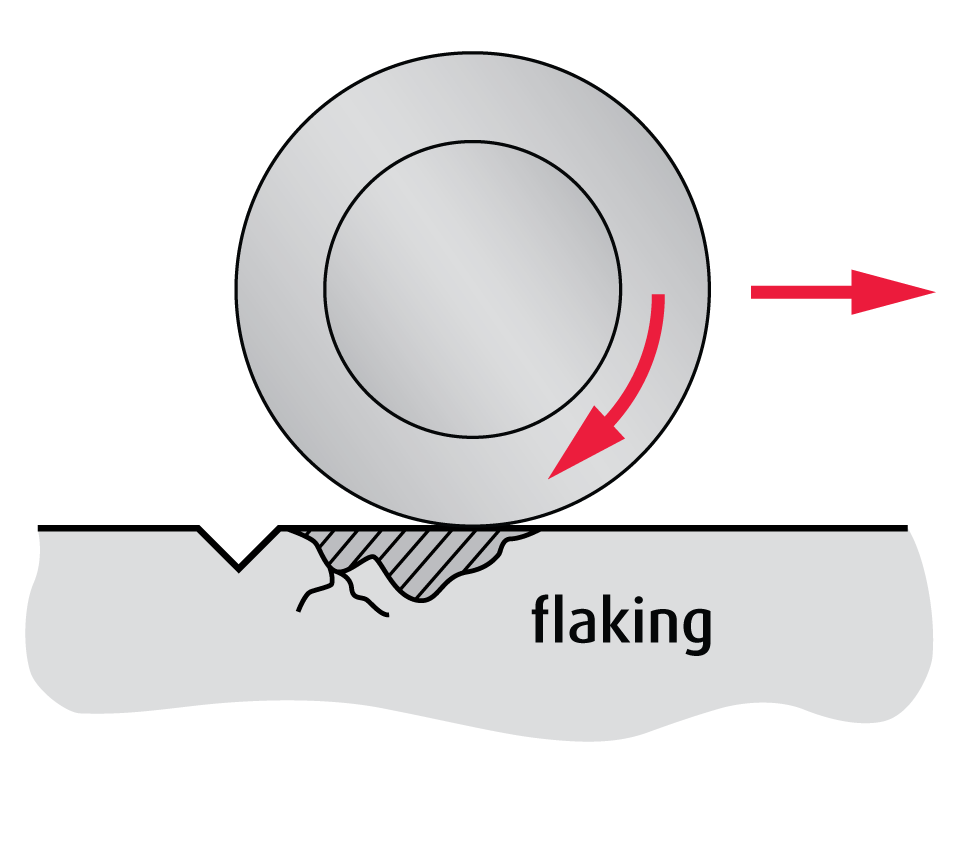

Stage 3: Flaking Development

Cracks propagate under the load of each passing roller and develop into flaking

Development of Super-TF Bearings

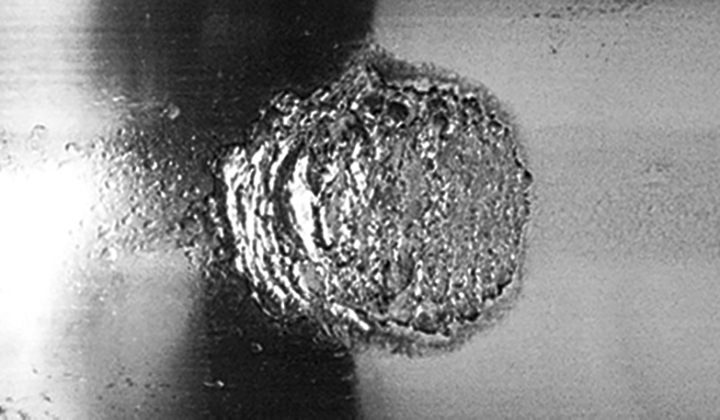

Operating Conditions

| Harsh operating conditions: heavy loads, low speeds | ||

| Foreign debris contamination: fine iron powder | Poor oil film formation: boundary-lubrication | |

| Bearing damage: surface originated flaking | |

|

|

Pictured: outer ring raceway surface flaking

Countermeasures

| Material composition | Containing appropriate levels of chromium and molybdenum for increased hardness |

| Special heat treatment | Optimized dispersion of finer carbide and carbonitride particles |

| Retained austenite | Alleviation of the stress concentration on the contact surface |

Super-TF Bearings

|

Super-TF Performance Life test result under foreign contamination

Life test result under boundary-lubrication (∆=0.3)

|