NSK Case Study

Application

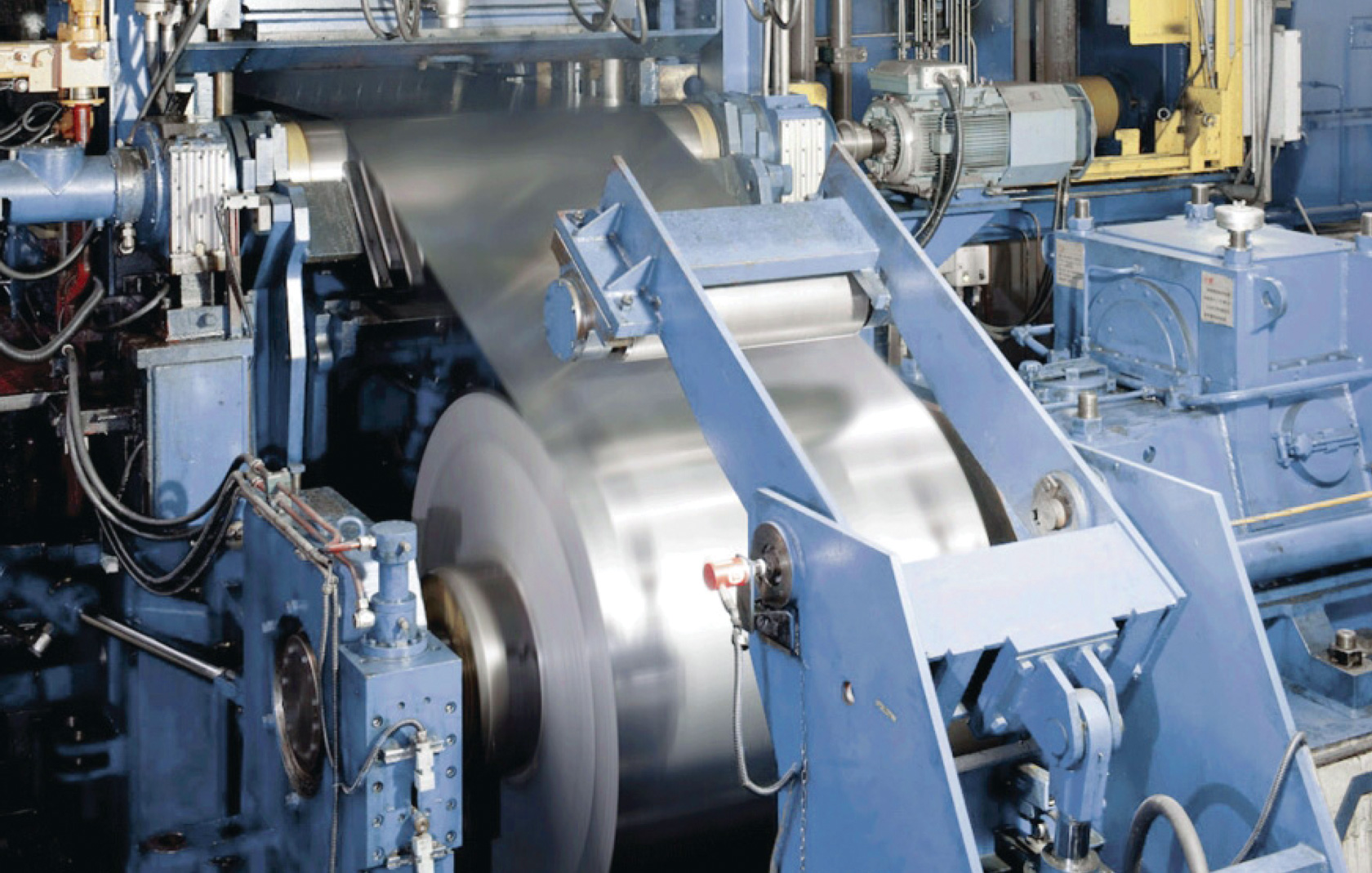

Cold Rolling Mill:

Steel Strip

Cost Savings: $28,288

A major steel producer was dissatisfied with the performance of their Four-Row Tapered Roller Bearings installed in their cold rolling mill. Steel shavings from the production process were entering the bearings resulting in a detrimental effect on bearing reliability. NSK performed a detailed on-site analysis of the bearings along with inspecting a failed bearing and lubrication analysis. After thorough review, a recommendation was made to adopt NSK Tough Steel technology which offers an excellent resistance to damage caused by the ingress of contamination.

Cold Rolling of Steel

Key Facts

|

Cold rolling mill |

|

Damage of the bearings due to ingress of steel shavings from the production process |

|

NSK solution: Bearings of Water Tough (WTF) steel |

|

More than 3X longer bearing life – reducing bearing consumption, downtime and maintenance costs |

Value Proposals

|

Analysis of the bearings, grease, structure and roll design |

|

NSK WTF steel bearings – designed for extreme operating conditions including solid and liquid contamination – were recommended |

|

Technical support including on-site engineering consultancy and lab-based bearing analysis |

Product Features

|

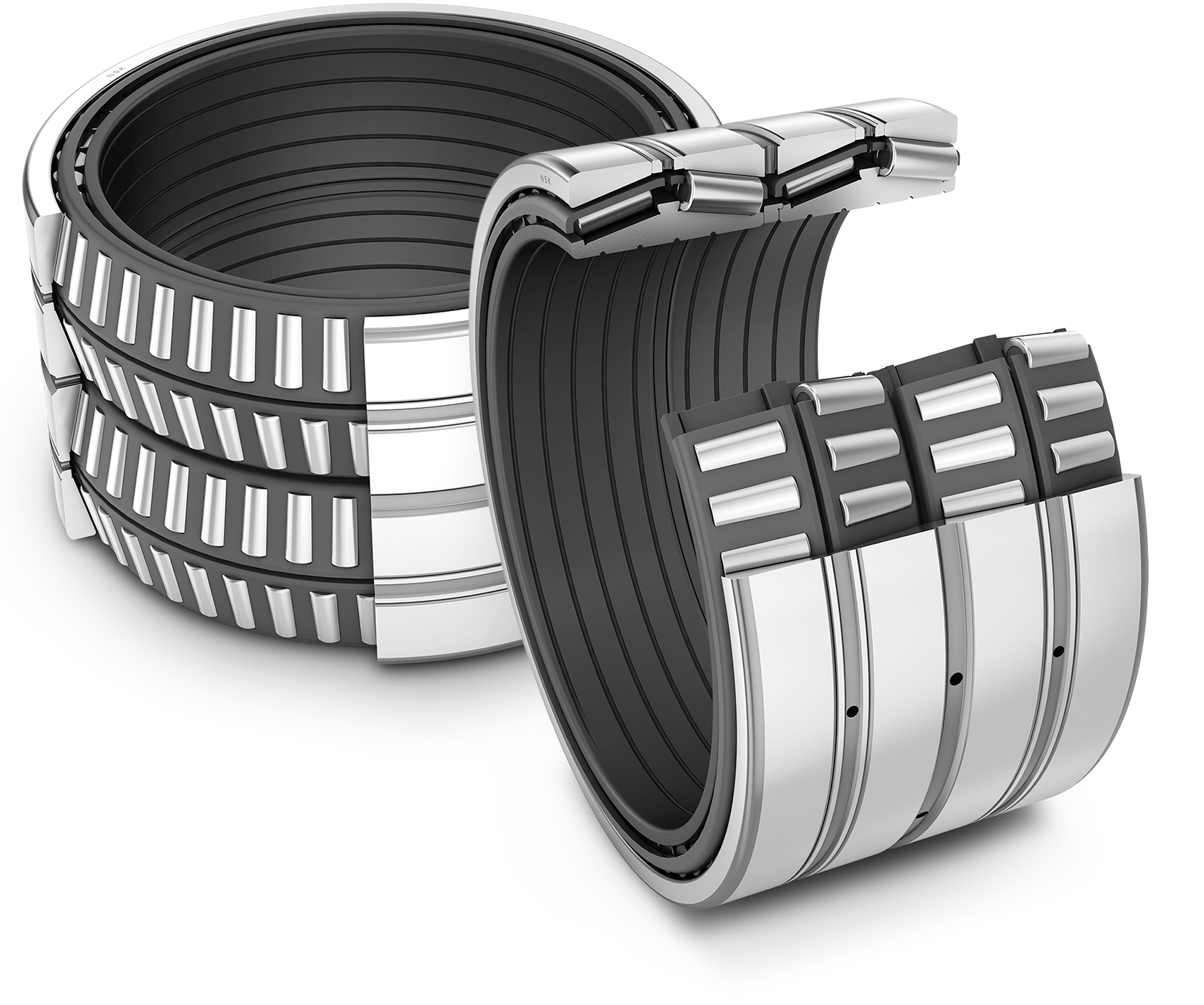

Advanced WTF (Water-Tough) material composition containing appropriate levels of chrome and molybdenum for increased hardness |

|

Innovative and patented heat treatment technology to optimize retained austenite and formation of finer carbide and carbonitride particles |

|

Significantly outperforms standard bearing steel in seizure resistance, rate of wear and service life |

|

Available for four-row cylindrical and four-row taper roller bearings |

|

Bearing life is 3 times longer than that of conventional bearing |

|

Grain boundaries have been strengthened to help prevent the propagation of cracks |

(Water Tough)

Tapered Roller Bearing

Cost-Savings Breakdown

| Before | Cost | NSK Solution | Cost | |||

|---|---|---|---|---|---|---|

| Bearing life of the previous bearings: 4 months, Lost production: $1,071/hr downtime X number of replacements X 4 unexpected downtimes per year | $47,147 | Bearing life of the new bearings: 12 months Lost production: $1,071/hr downtime X number of replacements X 1 unexpected downtime per year | $18,859 | |||

| Total Costs | $47,147 | Total Costs | $18,859 | |||

| Before | Cost | |

|---|---|---|

| Bearing life of the previous bearings: 4 months, Lost production: $1,071/hr downtime X number of replacements X 4 unexpected downtimes per year | $47,147 | |

| Total Costs | $47,147 | |

| NSK Solution | Cost | |

|---|---|---|

| Bearing life of the new bearings: 12 months Lost production: $1,071/hr downtime X number of replacements X 1 unexpected downtime per year |

$18,859 | |

| Total Costs | $18,859 | |

Your Partner for Machine Optimization

Our AIP Added Value Program is based around a simple proposition: ‘improvement pays’. By working with you throughout the AIP Value Cycle, we will help you achieve improvements in machine reliability, productivity and performance, all of which carry a tangible and measurable cost benefit – and we have the tools to prove it! That’s what we mean by improvement pays.

PDF Download

PDF Download