NSK Case Study

Application

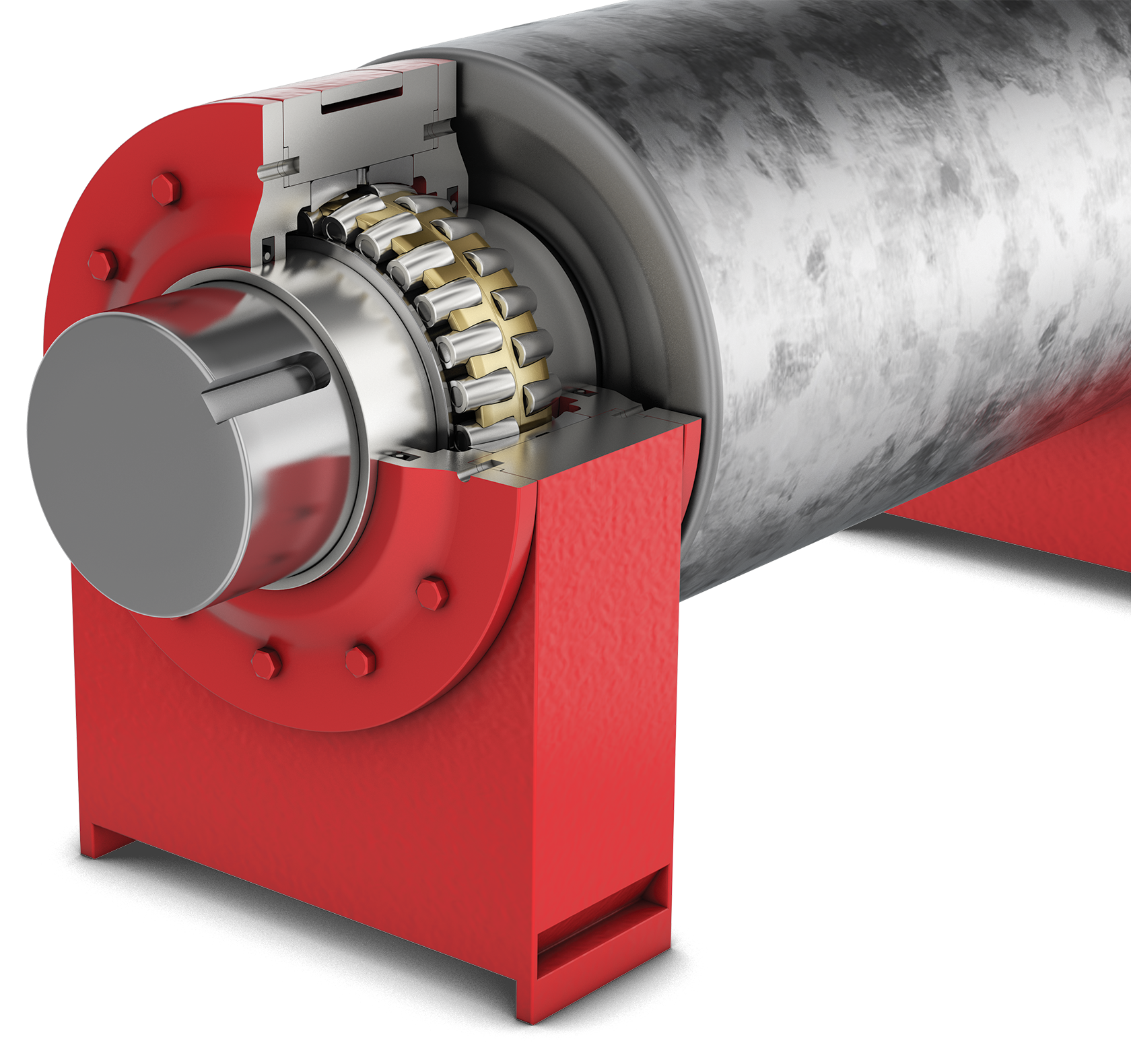

Continuous Casting Machine:

Shaped Sections

Cost Savings: $150,086

An international steel manufacturer was experiencing regular failures on bearings in a continuous casting machine. The machine is used in the production of shaped sections and as a result the bearings have to accommodate extremely heavy loads. Wear and fatigue were resulting in premature bearing failure, with 3 failures to date. After an investigation of the application, NSK suggested a durability test with NSK’s SWR™ Spherical Roller Bearings. SWR bearings are made of specially developed bearing steel, which has much better wear resistance against fatigue.

Key Facts

|

Continuous Casting Machine |

|

Wear and fatigue caused short bearing life |

|

Heavy operation conditions |

|

Longer bearing lifetime and reduced maintenance costs requested |

Value Proposals

|

NSK engineers conducted an Application Review including a Bearing Condition Report |

|

As a result, a trial utilizing Super Wear-Resistant (SWR) Spherical Roller Bearings was recommended |

|

The SWR bearings achieved 60% longer life |

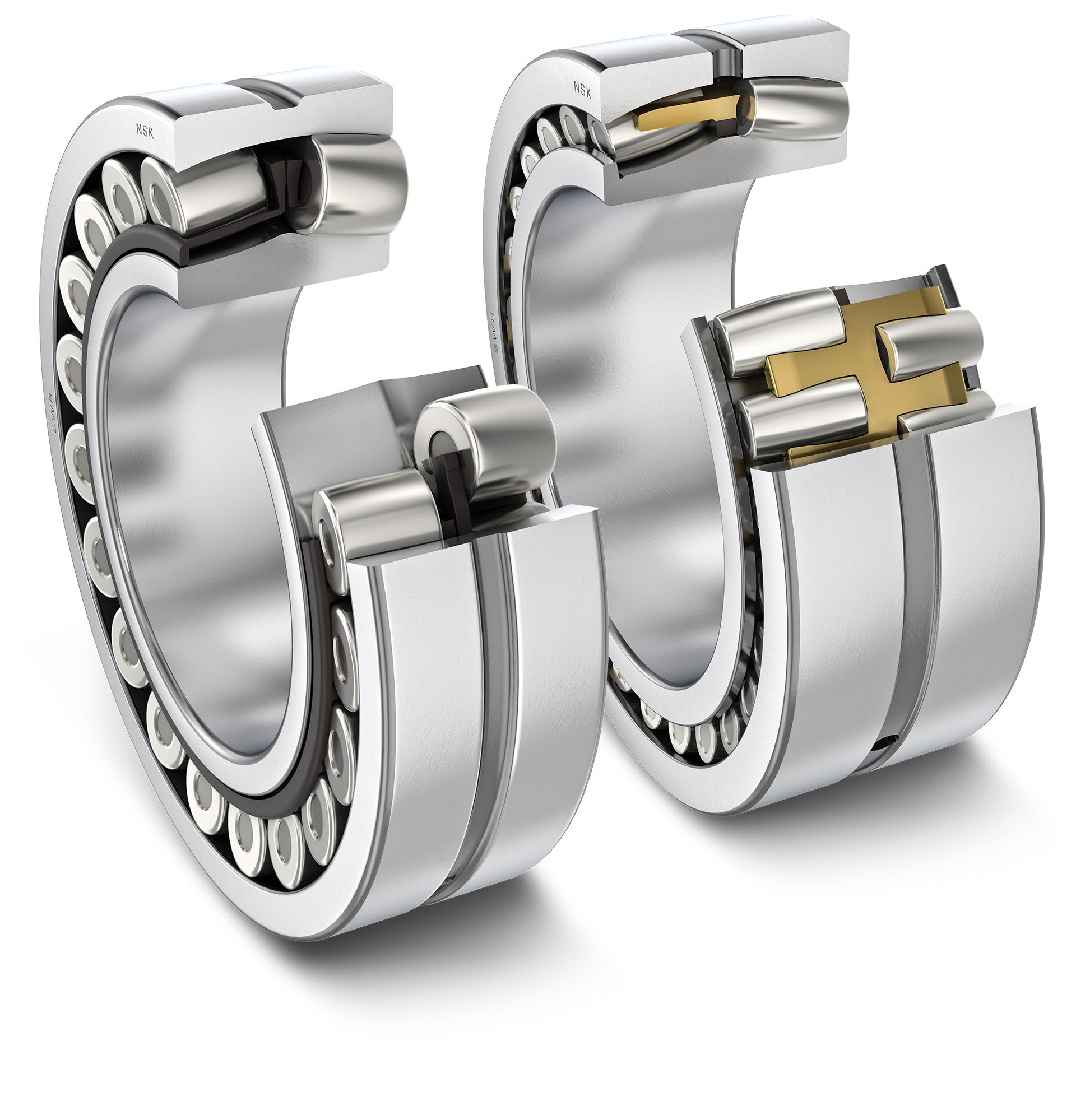

Product Features

|

Optimized, high-capacity internal design |

|

Outer rings manufactured with proprietary SWR steel composition and heat-treatment process |

|

With wear-resistant surface treated pressed steel and heavy-duty machined brass cages |

|

Superior wear resistance – 3 times that of conventional bearing steel |

|

Improved flaking life property – 5 times that of conventional bearing steel |

|

Higher toughness of material core (prevention of crack damage) – 5 times that of conventional bearing steel |

|

Improved bearing durability extends segment roll operation, reducing maintenance costs and preventing unplanned downtime |

Roller Bearings

Cost-Savings Breakdown

| Before | Cost | NSK Solution | Cost | |||

|---|---|---|---|---|---|---|

| Loss of production due to bearing failures | $107,204 | No production loss | $0 | |||

| Maintenance | $42,882 | No maintenance | $0 | |||

| Total Costs | $150,086 | Total Costs | $0 | |||

| Before | Cost | |

|---|---|---|

| Loss of production due to bearing failures | $107,204 | |

| Maintenance | $42,882 | |

| Total Costs | $150,086 | |

| NSK Solution | Cost | |

|---|---|---|

| No production loss |

$0 | |

| No maintenance | $0 | |

| Total Costs | $0 | |

Your Partner for Machine Optimization

Our AIP Added Value Program is based around a simple proposition: ‘improvement pays’. By working with you throughout the AIP Value Cycle, we will help you achieve improvements in machine reliability, productivity and performance, all of which carry a tangible and measurable cost benefit – and we have the tools to prove it! That’s what we mean by improvement pays.

PDF Download

PDF Download