Rolling Mills

Hot Rolling –

Strip

Extending Uptime in

Extreme Environments

As a hot strip of steel passes through a series of rolling stands that reduce and alter its shape and length, the supporting bearings must endure relentless punishment in the form of high heat, heavy and impact loads, variable speeds with rapid accelerations, and the constant presence of cooling water. All while running with accuracy to meet increasingly stringent standards for precision in rolled steel.

Here, NSK delivers our highest capacity bearing solutions – not only to withstand the heavy radial, axial and impact loads transmitted in work rolls and back-up rolls, but to deliver operating reliability in a water- and contaminant-laden operating environment.

Application-Optimized Solutions

Amid high heat, mill scale and water penetration, NSK Super-TF Sealed-Clean Work Roll Bearings deliver long-life wear and contaminant resistance for reduced bearing replacement and grease consumption.

Bearing Products

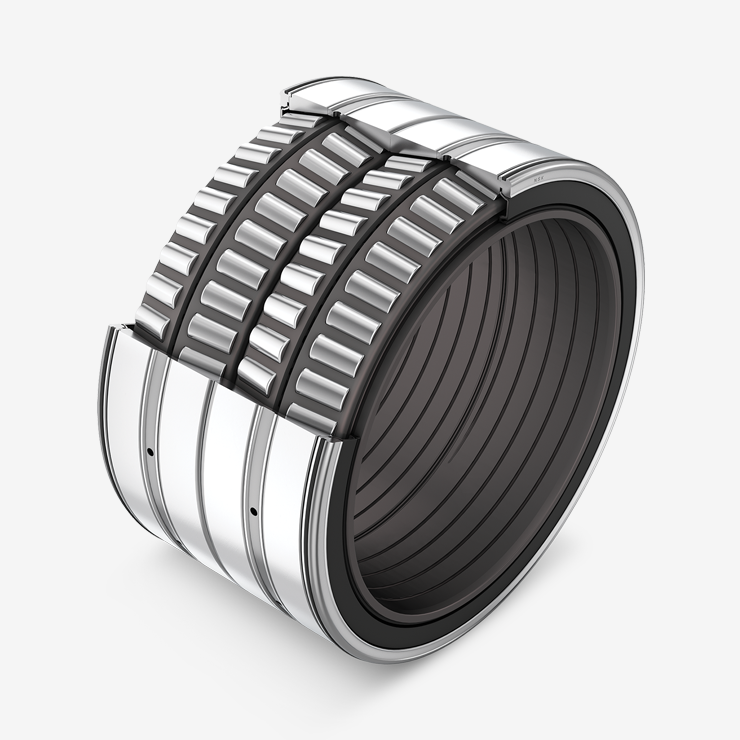

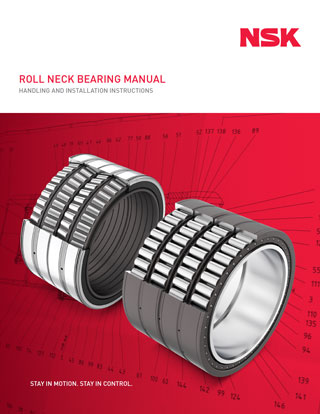

Four-Row Tapered Roller Bearings

Featuring NSK’s Sealed-Clean design for improved heat- and water-resistant protection.

Four-Row Cylindrical Roller Bearings

Accommodate extremely heavy and impact loads – while running with high rotational accuracy.

Double-Row Tapered Roller Bearings

Withstand heavy radial loads and thrust load support in back-up rolls.

Literature

|

Super-TF Sealed-Clean Four-Row Tapered Roller Bearings

|

|

Super-TF Four-Row Cylindrical Roller Bearings

|

|

Long-Life Water-Resistant Bearing Grease

|

|

Roll Neck Bearing Manual

|

Case Studies

|

Hot Strip Mill

|

|

Plate Rolling Mill

|

MORE

MORE