Continuous Casting

Segment Rolls

Top-End Performance

at the Top End

Bearings in continuous casting segments are exposed to unimaginably punishing stressors. Intense heat, massive loads, ultra-low speeds, water intrusion, scale, and mold powder contamination are constant challenges to operating life. Unplanned stoppage here is costly – in maintenance and replacement – and potentially impacts all downstream operations with lost production.

NSK segment bearing solutions have been purpose-engineered to withstand the environmental and mechanical forces prevalent in continuous casting applications. Advanced material and design technology is applied to effectively resist wear and support reliable roll operation.

Application-Optimized Solutions

With extreme durability and core toughness, NSK SWR™ Spherical Roller Bearings are engineered to deliver superior resistance to wear and the onset of progressive bearing damage in guide rolls of continuous casting machines.

Bearing Products

SWR™ Spherical Roller Bearings

Extreme durability and core toughness to deliver superior resistance to wear and the onset of progressive bearing damage.

NUB Cylindrical Roller Bearings

Accommodating roll shaft bending and expansion while running with reduced sliding friction and wear in strand guide rolls.

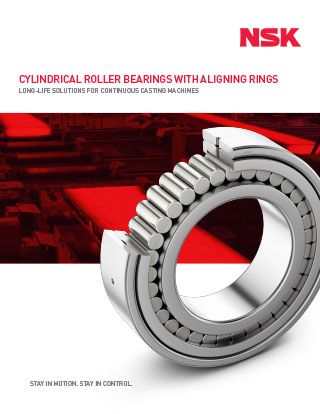

RUB Cylindrical Roller Bearings

Smooth accommodation of roll extension, with self-aligning capabilities to counteract misalignment and shaft deflection.

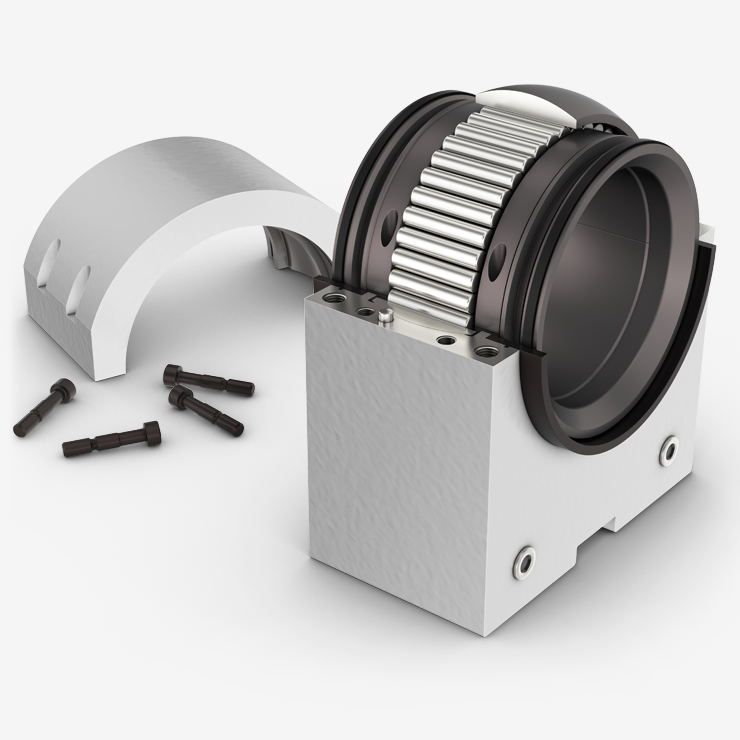

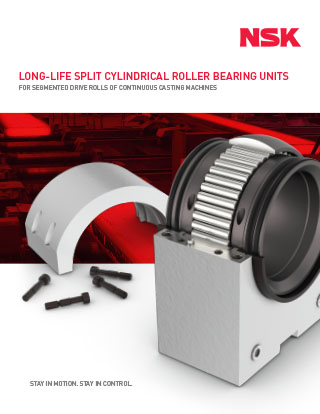

Split Cylindrical Roller Bearing Units

Eliminating roll dismantling for simplified bearing replacement in segmented drive rolls of continuous casting lines.

Literature

|

SWR™ Series Spherical Roller Bearings

|

|

NUB Series Cylindrical Roller Bearings

|

|

RUB Series Cylindrical Roller Bearings

|

|

Long-Life Split Cylindrical Roller Bearing Units

|

Case Studies

|

Continuous Casting Machine

|

|

Continuous Casting Machine – Shaped Sections

|

MORE

MORE